EPS/EPP/ETPU Mold Manufacturer

Main Markets

Africa

South America

Mid East

Some of our product

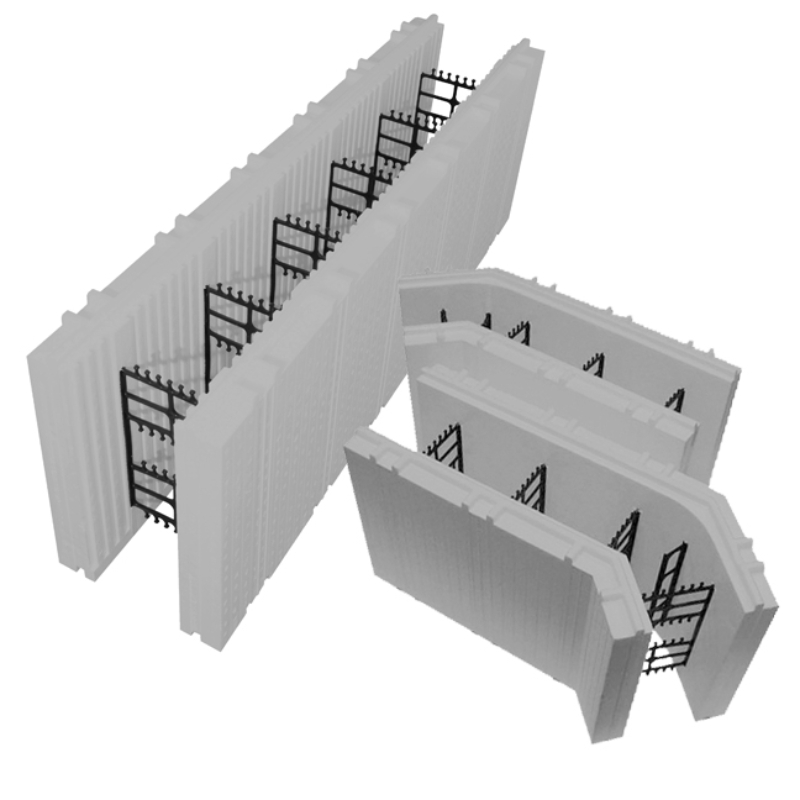

Styrofoam ICF Blocks

Styrofoam ICF blocks are used in construction to create insulated concrete walls.

Styrofoam Fish Box

Styrofoam fish boxes are used for storing and transporting fresh fish and seafood.

EPS Packaging Box

EPS packaging boxes are used for packaging fragile items such as medical supplies.

EPP fruit box mold

EPP fruit box mold refers to the mold of the fruit box made of foamed polypropylene.

EPP pallet mold

EPP pallet mold is used for manufacturing pallets made of expanded polypropylene.

EPP flower plant mold

EPP flower and plant molds are used to make flower and plant planting containers.

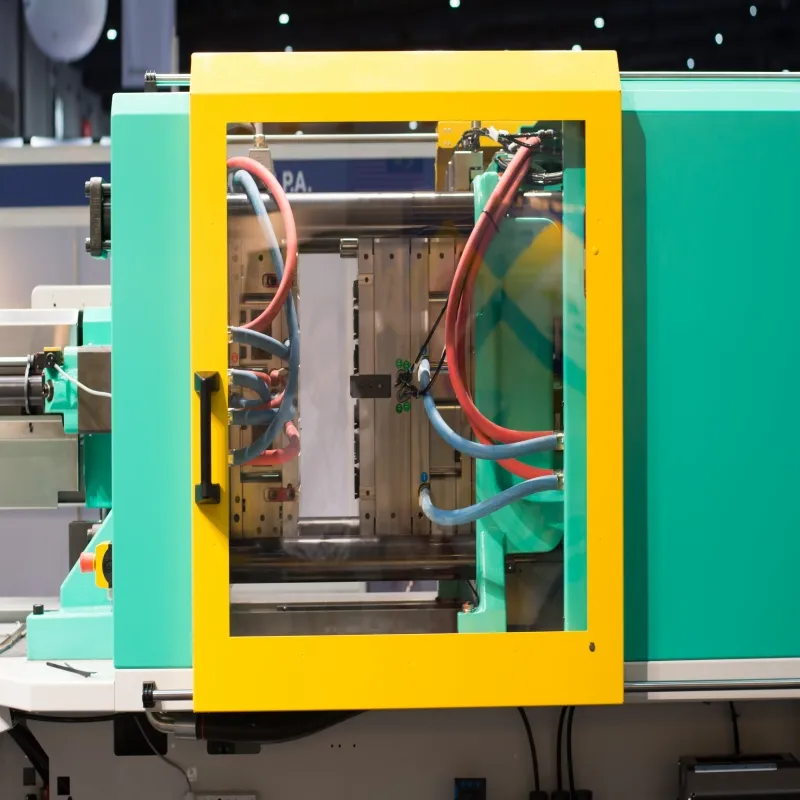

Production Process

Why Choose Us

Unmatched Quality

Our molds are crafted with precision and the highest quality materials, ensuring durability and reliability in every product.

Competitive Pricing

Our competitive pricing ensures you get the best value without compromising on quality or service.

Innovative Design

We offer cutting-edge design solutions tailored to meet your specific needs, enhancing efficiency and performance.

Technical Services

With years of industry experience, our skilled team brings unparalleled expertise to every project, guaranteeing superior results.

What They Are Saying

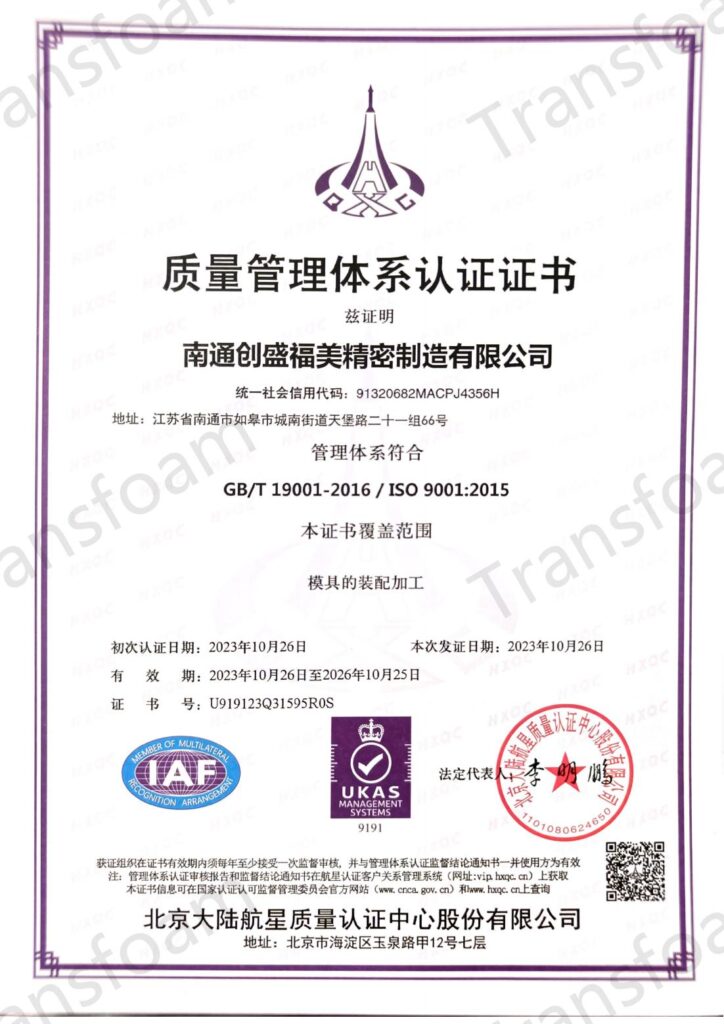

Certification

Book Your Visit

The manufacturing cost of foam plastic mold depends on factors such as material, process and complexity, and generally ranges from several thousand to tens of thousands of yuan.

Foam plastic molds need regular cleaning, lubrication, inspection and maintenance to ensure their normal use and prolong their life.

The fault handling of the foam plastic mold needs to be analyzed and dealt with according to the fault type, cause and influence and other factors.

The dimensional accuracy of the foam plastic mold depends on multiple links such as design, processing and debugging, and the quality of each link needs to be strictly controlled.

Foam plastic molds are widely used in the manufacture of products in industries such as electronics, automobiles, medical equipment, and home appliances.