What is Blow Molding?

Blow molding is a highly efficient manufacturing process used to produce hollow plastic parts. Think about the plastic bottles you drink from daily—chances are, they were made using blow molding. This technique involves inflating a hot plastic tube, known as a parison, inside a mold cavity until it conforms to the shape of the mold. The result? A perfectly formed, hollow plastic object.

This method is incredibly popular because it’s cost-effective, scalable, and capable of creating consistent, lightweight, and durable products. Whether it’s a small shampoo bottle or a massive fuel tank, blow molding handles it all with precision. It’s often compared to glassblowing, which works on a similar principle—shaping by blowing air into a material.

Blow molding stands out in the plastic manufacturing world for its ability to handle high volumes without compromising on quality. With growing demands in packaging, automotive, and consumer goods, understanding blow mold technology is more important than ever.

History and Evolution of Blow Molding

The concept of blow molding isn’t exactly new. It actually has roots dating back to the first century BC when glassblowing was invented by the Syrians. However, it wasn’t until the 1930s that blow molding began to evolve into the plastic-focused process we know today. The first blow molding machine was developed in the 1930s by the Hartford Empire Company, and the plastic revolution took off shortly after World War II.

The 1950s and ’60s marked a turning point with the introduction of high-density polyethylene (HDPE). This allowed manufacturers to produce everything from milk jugs to detergent bottles. As materials and technology advanced, so did the blow molding machines. Today’s systems are fully automated, computer-controlled, and capable of producing millions of units efficiently.

Over the decades, the blow molding industry has grown exponentially. Innovations in mold design, automation, and material science have made the process faster, more energy-efficient, and highly adaptable to a range of industries. Blow molding now plays a critical role in modern manufacturing, contributing to everything from packaging to industrial applications.

How Does Blow Molding Work?

The basic steps of blow molding include:

- Melting Plastic – Plastic resin is heated until it becomes molten.

- Forming a Parison/Preform – The melted plastic is shaped into a tube (extrusion blow molding) or a preform (injection/stretch blow molding).

- Inflating the Plastic – Compressed air is blown into the plastic, forcing it to expand against the mold walls.

- Cooling & Ejection – The plastic cools and hardens, then the finished product is ejected.

Types of Blow Molding Processes

There are three primary blow molding techniques, each suited for different applications:

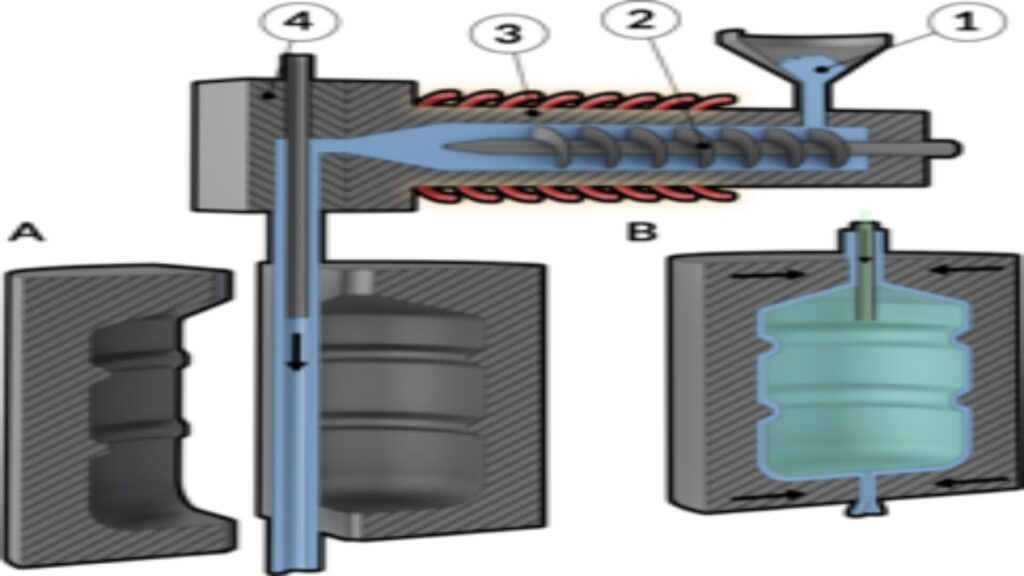

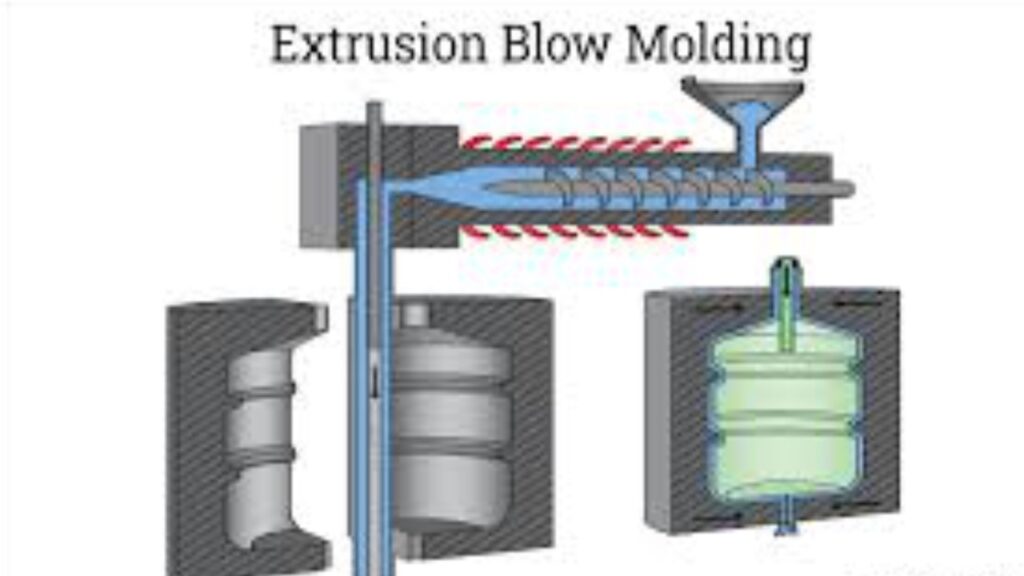

1. Extrusion Blow Molding (EBM)

Extrusion blow molding (EBM) is perhaps the most widely used form of this technology. The process begins with melting plastic and extruding it into a hollow tube called a parison. Once the parison is in place, it’s clamped between two mold halves and air is blown inside to force the plastic against the mold walls.

This method is especially suited for making containers like bottles, drums, and tanks. The biggest advantage of EBM is its ability to create complex shapes with handles or curves. It’s also ideal for producing larger parts that don’t require high precision in thickness distribution.

Manufacturers love EBM because of its high output and ability to work with various thermoplastics. The tooling costs are relatively low, and mold changes are quick—making it ideal for short runs or frequent product updates.

Applications:

- Water bottles

- Fuel tanks

- Household containers

Advantages:

- Cost-effective for large production runs

- Suitable for complex shapes

- Wide range of material options

2. Injection Blow Molding (IBM)

Injection blow molding (IBM) is a two-step process that starts by injecting molten plastic into a mold to form a preform. This preform is then transferred to a blow mold where it’s inflated into its final shape. This method combines the precision of injection molding with the flexibility of blow molding.

IBM is ideal for making smaller, high-precision containers—think pharmaceutical bottles, travel-size toiletries, and cosmetic packaging. Because the preform is precisely molded, you get much better control over wall thickness and surface finish.

While IBM offers excellent part consistency and detail, it’s generally slower and more expensive than extrusion blow molding. It also requires more complex equipment and mold design, which may not be cost-effective for large or simple products.

Still, for high-value applications where detail and quality matter more than speed or volume, IBM is the go-to method.

Applications:

- Pharmaceutical bottles

- Cosmetic containers

- Small medical devices

Advantages:

- Excellent dimensional accuracy

- No trimming required

- Ideal for small, high-quality products

3. Stretch Blow Molding (SBM)

Stretch blow molding (SBM) is mostly used for producing PET bottles—like soda and water bottles. It involves stretching the preform both axially and radially during the blowing process. This orientation improves strength, clarity, and barrier properties of the final product.

There are two main types of SBM: single-stage and two-stage. In single-stage SBM, the preform is made and blown in one continuous process. In two-stage SBM, the preform is made first, stored, and later reheated and blown.

SBM allows for ultra-lightweight bottles that still meet rigorous strength and performance standards. This is particularly crucial in the beverage industry, where saving even a gram of plastic per bottle translates to massive cost and environmental savings.

Though more complex than EBM or IBM, SBM provides unparalleled performance for applications needing crystal-clear packaging, high-pressure resistance, or long shelf life. That’s why it dominates in the soft drink and bottled water markets.

Applications:

- Carbonated drink bottles

- Juice containers

- Water bottles

Advantages:

- Enhanced strength and clarity

- Lightweight yet durable

- High production speed

The Blow Molding Process Step-by-Step

Designing the Mold

Before any plastic is melted or shaped, everything starts with the mold. Mold design is the foundation of successful blow molding. It defines not only the shape and size of the product but also affects the cooling rate, cycle time, and material distribution.

Mold designers must consider multiple factors: draft angles, wall thickness, cooling channels, and parting lines. These design elements determine how easily the part will release from the mold, how evenly it cools, and how durable the mold will be over time.

Using advanced CAD software and simulations, designers can now test how the plastic will flow and stretch within the mold before a single prototype is made. This minimizes costly errors and shortens development time.

Precision in mold design pays off in reduced scrap, shorter cycle times, and improved product consistency. Whether the mold is for a tiny 5ml dropper bottle or a 50-gallon drum, thoughtful design is everything.

Material Preparation and Selection

Choosing the right material isn’t just a technical decision—it impacts cost, functionality, and recyclability. Common materials include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polyvinyl chloride (PVC).

Each material brings its own set of pros and cons. For example:

- HDPE: Great for durability and chemical resistance (used in detergent bottles).

- PET: Offers excellent clarity and strength (perfect for beverage bottles).

- PP: Known for flexibility and heat resistance (used in automotive parts).

- PVC: Offers good clarity and toughness (used in medical containers).

Before production begins, the plastic resin must be dried and conditioned. Moisture in the resin can cause bubbles or weak spots in the final product. Ensuring proper material prep is just as vital as mold design in ensuring a flawless finished product.

Heating and Molding

The actual transformation begins with heating the plastic resin until it reaches a molten state. This is where the magic of blow molding really starts. In extrusion blow molding, the plastic is melted and extruded into a vertical tube, called a parison. In injection and stretch blow molding, preforms are heated until they become pliable enough for blowing.

Precise temperature control is key. If the plastic is too cold, it won’t form properly; too hot, and it could sag or burn. Every resin type has its own ideal processing temperature. For instance, PET generally requires higher temperatures than HDPE. Manufacturers often use infrared heaters or hot air systems to ensure even heating across the material.

Once heated, the parison or preform is clamped inside the mold. Compressed air is then blown inside, expanding the plastic against the mold’s inner walls. This step happens in milliseconds, yet the results are exact replicas of the mold cavity. It’s during this stage that the product’s final shape, thickness, and surface texture are determined.

This process may look seamless, but it involves a deep understanding of fluid dynamics, thermal expansion, and material science. Even a small inconsistency in heat or air pressure can cause defects like wrinkles, bubbles, or uneven thickness—issues that manufacturers are constantly trying to minimize.

Cooling and Ejection

After the part takes shape, it’s crucial to cool it down evenly and quickly. Cooling helps the product retain its new form and ensures structural integrity. In most molds, internal water channels or air-cooling systems are embedded to accelerate this step.

The cooling time depends on the plastic type, wall thickness, and size of the part. Thicker sections take longer to solidify, which can slow down cycle times. That’s why product and mold designers aim for uniform wall thickness to optimize this phase.

Once sufficiently cooled, the mold opens, and the finished product is ejected. Automated arms or conveyors then move the part to the next station—whether that’s quality inspection, trimming, or packaging.

While it might sound like a simple step, proper ejection is critical. Poor mold release can deform the product or even damage the mold. Lubricants and ejector pins are often used to assist the process and ensure a smooth release without damaging the surface of the plastic part.

This entire process—from heating to ejection—typically takes just seconds. However, manufacturers must strike a balance between speed and quality. Faster cooling means quicker cycles, but can lead to internal stress or warping. With the help of modern automation and sensors, today’s blow molding systems are more efficient and reliable than ever.

Materials Used in Blow Molding

The choice of material affects the product’s strength, flexibility, and chemical resistance. Common materials include:

- Polyethylene (PE) – Used for milk jugs, detergent bottles.

- Polyethylene Terephthalate (PET) – Ideal for beverage bottles.

- Polypropylene (PP) – Used for food containers and automotive parts.

- Polyvinyl Chloride (PVC) – Common in medical and industrial applications.

- High-Density Polyethylene (HDPE) – Used for fuel tanks and chemical containers.

Each material has unique properties, making it essential to select the right one based on the product’s requirements.

Key Advantages of Blow Molding

Blow molding offers several benefits over other manufacturing methods:

Cost-Effective Production – Ideal for high-volume manufacturing with low per-unit costs.

Design Flexibility – Can produce complex shapes and custom designs.

Lightweight & Durable – Plastic products are strong yet easy to transport.

Fast Production Cycles – Modern machines enable rapid manufacturing.

Recyclability – Many blow-molded products can be recycled, supporting sustainability.

Applications of Blow Mold Technology

Packaging Industry

If you’ve ever opened a plastic bottle of soda, poured milk from a jug, or used shampoo from a squeeze bottle, you’ve interacted with blow-molded products. Packaging is hands down the biggest user of blow molding. Why? Because it offers unmatched efficiency for producing high-volume, low-cost, and uniform containers.

Blow molding dominates the beverage industry, thanks to PET’s excellent clarity and strength. Think soda bottles, water bottles, juice containers—all are made using stretch blow molding. HDPE is the king of household packaging, handling everything from cleaning supplies to cooking oil.

The appeal of blow molding in packaging isn’t just affordability. It’s also customization. Manufacturers can easily change mold designs to create bottles of various shapes, sizes, and branding features like embossed logos or unique caps.

Moreover, the packaging industry demands rapid turnaround times. Blow molding machines can produce thousands of units per hour, all with minimal human intervention. This makes the process not only economical but also highly scalable.

The rise in e-commerce has further fueled demand for durable, lightweight, tamper-resistant packaging—all strengths of blow-molded products. With sustainability trends growing, there’s also a push toward lightweighting and recyclable materials in packaging, areas where blow molding continues to adapt and excel.

Automotive and Industrial Applications

Blow molding isn’t just for making bottles—it plays a major role in the automotive and industrial sectors too. These industries rely heavily on durable, lightweight, and complex-shaped components, which blow molding is uniquely suited to deliver.

In cars, you’ll find blow-molded parts like:

- Fuel tanks

- Air ducts

- Seat support structures

- Battery cases

- Fluid reservoirs (windshield washer and coolant tanks)

These components benefit from the seamless, single-piece construction that blow molding offers. Fewer seams mean fewer points of failure, which is crucial for parts that need to handle pressure or fluid containment.

For industrial use, blow molding creates items like large drums, tool cases, shipping containers, and even construction barriers. The technology allows for thick-walled parts that can withstand wear and tear, extreme temperatures, and chemical exposure.

HDPE and PP are common materials here due to their impact resistance and chemical durability. With innovations in multi-layer blow molding, parts can even have different materials layered together—for instance, an oxygen-barrier layer sandwiched between two HDPE layers for fuel tanks.

With automation and robotics becoming increasingly integrated into the production line, the automotive and industrial applications of blow molding are only expanding. OEMs (Original Equipment Manufacturers) appreciate the cost-efficiency and flexibility, while engineers value the design freedom and performance characteristics.

Medical and Household Uses

The medical industry demands high precision, cleanliness, and reliability—three things that modern blow molding can provide in spades. It’s used to produce items like:

- Disposable containers

- Respiratory device parts

- Medical waste containers

- Pharmaceutical packaging

Because medical-grade plastics must meet strict regulatory requirements (like USP Class VI or FDA standards), the blow molding process needs to be extremely controlled. Cleanroom blow molding facilities are common, ensuring contamination-free production.

Household goods are another large category. Blow molding produces common items such as:

- Watering cans

- Storage bins

- Trash cans

- Toys

- Laundry detergent bottles

The advantages? Lightweight design, customizable shapes, and low production costs. Products can be designed with ergonomic features, like handles and grips, or made translucent so users can see the contents.

This is also where aesthetic considerations come into play. With colorants, surface textures, and labeling options, blow-molded household items can be made visually appealing while still being functional.

Advantages and Disadvantages of Blow Molding

Benefits of Blow Molding

Blow molding has earned its place as a go-to manufacturing method for hollow plastic parts, and for good reason. Here’s why businesses and industries rely on it:

- Cost-Effective for Mass Production: Once the mold is made, the per-unit cost drops dramatically, making it ideal for high-volume runs.

- Design Flexibility: Complex shapes, curves, handles, and threads can be easily integrated into the mold.

- Lightweight yet Strong: Products can be thin-walled and light while still being durable and resistant to impact.

- Fast Production: Machines can produce thousands of parts per hour with minimal waste.

- Scalable: Blow molding accommodates everything from small runs to global production volumes.

- Material Versatility: A wide variety of plastics can be used, many of which are recyclable.

Limitations and Challenges

Despite its many benefits, blow molding isn’t perfect. Here are a few drawbacks:

- Initial Mold Cost: Designing and manufacturing molds can be expensive and time-consuming.

- Wall Thickness Variation: Some blow molding methods result in uneven thickness, which can compromise structural integrity.

- Design Restrictions: Extremely detailed or intricate shapes are difficult to achieve compared to other molding techniques.

- Environmental Impact: Though many plastics are recyclable, blow molding still relies heavily on petroleum-based materials.

- Tooling Time: Switching between products or materials can require downtime for mold changes and recalibration.

Understanding these limitations helps businesses decide if blow molding is the right choice—or whether another process like injection molding or rotational molding might better suit their needs.

Blow Mold vs. Injection Molding

Blow molding and injection molding are often compared, but they serve different purposes and produce very different results. Let’s break down the key differences:

| Feature | Blow Molding | Injection Molding |

|---|---|---|

| Product Type | Hollow parts (bottles, containers) | Solid parts (caps, gears, toys) |

| Process | Air inflates plastic in mold | Molten plastic injected into mold |

| Speed | Faster for hollow objects | Faster for detailed solid objects |

| Complexity | Good for simple, uniform shapes | Excellent for detailed, intricate parts |

| Cost | Lower for high-volume hollow items | Higher for complex precision parts |

| Applications | Packaging, automotive tanks | Electronics, automotive components |

In summary, blow molding is your best bet for hollow, lightweight parts. Injection molding shines when you need precise, complex shapes. The two methods often complement each other—think blow-molded bottles with injection-molded caps.

Emerging Trends in Blow Molding Technology

The blow molding industry is evolving with new innovations:

Automation & Industry 4.0 – Smart machines with IoT integration improve efficiency.

Sustainable Materials – Biodegradable and recycled plastics are gaining popularity.

3D Printing for Prototyping – Faster mold design and testing.

Energy-Efficient Machines – Reduced power consumption lowers costs.

Multi-Layer Blow Molding – Enhances barrier properties for food and pharmaceutical packaging.

Conclusion

Blow molding is a versatile and efficient manufacturing process used across multiple industries. From packaging to automotive components, this technology continues to evolve with automation, sustainability, and advanced materials.

By understanding the different blow molding techniques, materials, and applications, businesses can make informed decisions to optimize production and reduce costs.

Blow molding might not be the flashiest manufacturing process, but it’s one of the most important. From packaging our drinks to powering our cars, it’s everywhere—quietly shaping the world around us. Its versatility, speed, and cost-efficiency make it indispensable across multiple industries.

As materials get smarter and machines become more automated, the blow molding process will only grow more efficient, sustainable, and innovative. Whether you’re a product designer, manufacturer, or simply a curious consumer, understanding blow molding gives you a new appreciation for the everyday products we take for granted.