Expanded Polystyrene (EPS) foam is a versatile material widely used in various industries for packaging, insulation, and molding.

One common question that arises is whether you can pour water into an EPS foam mold.

Understanding EPS Foam

What is EPS Foam?

EPS foam, or Expanded Polystyrene, is a lightweight, rigid, and thermoplastic material derived from the polymerization of styrene.

It is composed of 98% air and 2% polystyrene, giving it excellent insulating properties and structural strength.

EPS foam is widely used for packaging, construction, and crafting due to its affordability, versatility, and ease of use.

Properties of EPS Foam

To understand whether water can be poured into an EPS foam mold, it’s essential to consider its properties:

1. Lightweight: EPS foam is extremely lightweight, making it easy to handle and transport.

2. Insulating: It has excellent thermal insulation properties, making it ideal for applications requiring temperature control.

3. Durable: EPS foam is resistant to moisture, chemicals, and biological degradation.

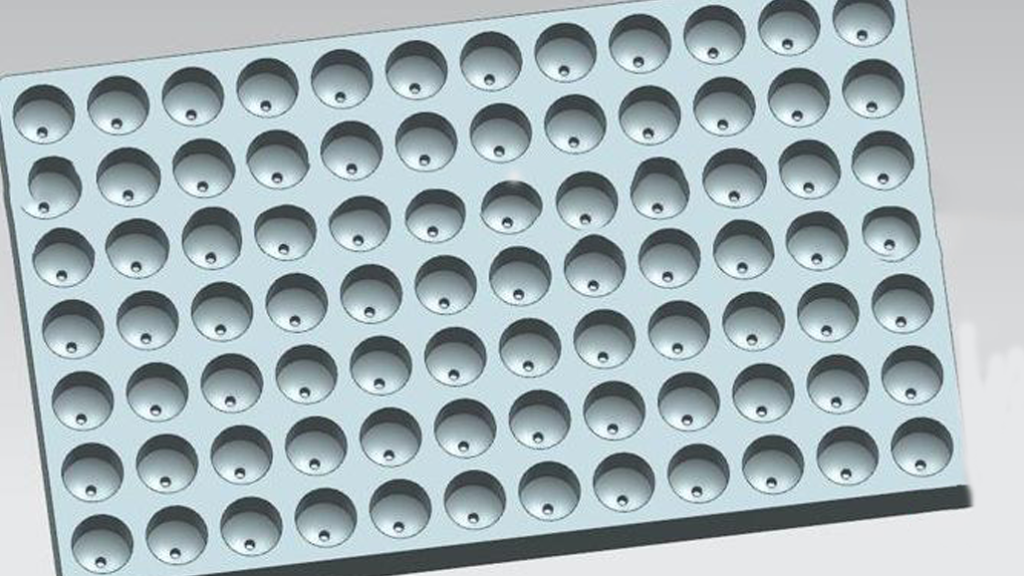

4. Moldable: It can be easily molded into various shapes and sizes, making it suitable for diverse applications.

5. Porous: EPS foam has a porous structure, which can impact its interaction with liquids.

Common Uses of EPS Foam Molds

EPS foam molds are used in various industries for applications such as:

– Packaging: Protecting fragile items during shipping and storage.

– Construction: Insulating buildings and creating architectural elements.

– Crafting: Creating models, prototypes, and decorative items.

– Medical: Molding custom orthotic devices and prosthetics.

Pouring Water Into an EPS Foam Mold: Key Considerations

Water Absorption and Permeability

EPS foam is known for its low water absorption properties.

However, it’s not entirely impermeable. When exposed to water, the outer surface of EPS foam may absorb a small amount of moisture, but it generally does not penetrate deeply into the material.

This characteristic makes EPS foam suitable for applications where exposure to moisture is minimal or controlled.

Potential Effects of Water on EPS Foam

When water is poured into an EPS foam mold, several factors come into play:

1. Surface Interaction: The water will primarily interact with the outer surface of the EPS foam mold. Due to the material’s low permeability, water is unlikely to penetrate deeply.

2. Structural Integrity: EPS foam retains its structural integrity when exposed to water. It does not swell, warp, or degrade, making it a reliable material for applications involving moisture.

3. Thermal Insulation: The insulating properties of EPS foam remain largely unaffected by water exposure, ensuring continued thermal performance.

Practical Applications

Pouring water into an EPS foam mold can have practical applications in various fields:

1. Concrete Casting: EPS foam molds are often used in concrete casting to create intricate shapes and designs.

Water is mixed with concrete, and the mixture is poured into the mold. The EPS foam mold provides a stable form for the concrete to set and harden.

2. Hydroponics: In hydroponic systems, EPS foam molds can be used to support plant roots while water and nutrients flow through the system.

The low water absorption of EPS foam helps maintain the integrity of the mold.

3. Art and Craft: Artists and crafters may use EPS foam molds to create water-based sculptures or models. The mold’s resistance to water ensures that it remains intact throughout the process.

Detailed Analysis: EPS Foam in Concrete Casting

The Role of EPS Foam Molds

EPS foam molds are extensively used in the construction industry, particularly in concrete casting. These molds offer several advantages:

– Customizability: EPS foam can be easily cut and shaped into complex designs, allowing for intricate concrete forms.

– Lightweight: The lightweight nature of EPS foam makes it easy to handle and position on construction sites.

– Cost-Effective: EPS foam molds are relatively inexpensive compared to traditional molds made from wood or metal.

– Disposable: After the concrete has set, EPS foam molds can be easily removed and discarded or recycled.

Process of Using EPS Foam Molds for Concrete Casting

1. Design and Fabrication: The desired shape of the concrete structure is designed, and an EPS foam mold is fabricated accordingly.

2. Preparation: The EPS foam mold is prepared by applying a release agent to prevent the concrete from sticking to the mold.

3. Pouring Concrete: The concrete mixture, containing water, cement, sand, and aggregates, is poured into the EPS foam mold.

4. Setting and Curing: The concrete is allowed to set and cure within the EPS foam mold. During this period, the mold provides structural support.

5. Demolding: Once the concrete has hardened, the EPS foam mold is carefully removed, revealing the final concrete structure.

Advantages of Using EPS Foam Molds in Concrete Casting

1. Precision: EPS foam molds enable the creation of precise and intricate concrete forms, enhancing the aesthetic appeal of the final structure.

2. Efficiency: The lightweight nature of EPS foam molds simplifies the casting process, reducing labor and time requirements.

3. Cost Savings: The affordability of EPS foam molds contributes to overall cost savings in construction projects.

4. Versatility: EPS foam molds can be used for various types of concrete structures, including walls, columns, and decorative elements.

Hydroponics: EPS Foam Molds in Water-Based Systems

EPS Foam and Hydroponics

Hydroponics is a method of growing plants without soil, using nutrient-rich water solutions.

EPS foam molds play a crucial role in hydroponic systems by providing support to plant roots while allowing water and nutrients to flow freely.

Benefits of EPS Foam in Hydroponics

1. Root Support: EPS foam molds securely hold plant roots, preventing them from becoming entangled or damaged.

2. Moisture Control: The low water absorption of EPS foam helps maintain an optimal moisture level around the roots, promoting healthy plant growth.

3. Lightweight: EPS foam is easy to handle and position within hydroponic systems, facilitating efficient setup and maintenance.

4. Reusable: EPS foam molds can be cleaned and reused multiple times, reducing waste and costs.

Setting Up an EPS Foam-Based Hydroponic System

1. Design and Fabrication: EPS foam molds are designed to accommodate the specific plant species and hydroponic system.

2. Nutrient Solution: A nutrient-rich water solution is prepared and circulated through the hydroponic system.

3. Plant Placement: Plants are placed in the EPS foam molds, with their roots extending into the nutrient solution.

4. Monitoring and Maintenance: The system is monitored to ensure optimal nutrient levels, pH, and moisture. EPS foam molds are periodically cleaned and inspected for wear.

Advantages and Disadvantages

Advantages

– Enhanced Plant Growth: EPS foam molds provide a stable and supportive environment for plant roots, promoting robust growth and high yields.

– Reduced Soil Dependency: Hydroponic systems using EPS foam molds eliminate the need for soil, reducing the risk of soil-borne diseases and pests.

– Efficient Resource Use: Hydroponic systems with EPS foam molds optimize water and nutrient use, minimizing waste and environmental impact.

Disadvantages

– Initial Setup Costs: The initial cost of setting up a hydroponic system with EPS foam molds can be higher compared to traditional soil-based methods.

– Maintenance Requirements: Regular monitoring and maintenance are required to ensure the optimal performance of the hydroponic system and EPS foam molds.

Artistic and Craft Applications

Creating Water-Based Sculptures with EPS Foam Molds

Artists and crafters often use EPS foam molds to create water-based sculptures and models. The properties of EPS foam make it an ideal material for these applications.

Benefits of EPS Foam in Art and Craft

1. Versatility: EPS foam can be easily shaped and carved into intricate designs, allowing for creative freedom.

2. Water Resistance: EPS foam’s low water absorption ensures that the molds remain intact during the creation of water-based sculptures.

3. Lightweight: The lightweight nature of EPS foam makes it easy to handle and maneuver during the crafting process.

Steps to Create Water-Based Sculptures

1. Design and Fabrication: The desired sculpture design is created, and an EPS foam mold is fabricated accordingly.

2. Preparation: The EPS foam mold is prepared by applying a release agent to facilitate easy removal of the sculpture.

3. Pouring Water-Based Mixture: A water-based mixturesuch as plaster or resin, is poured into the EPS foam mold.

4.Setting and Curing: The mixture is allowed to set and cure within the mold. The EPS foam mold provides structural support during this process.

5.Demolding and Finishing: Once the sculpture has hardened, the EPS foam mold is removed. The sculpture is then finished and detailed as needed.

To waterproof EPS foam molds, you can use several methods:

1. Coatings: Apply a waterproof coating such as epoxy resin, polyurethane, or acrylic sealants. These provide a durable, water-resistant layer over the foam.

2. Spray Sealants: Use spray-on waterproof sealants designed for foam materials. These penetrate the surface and create a waterproof barrier.

3. Plasti Dip: Dip or spray the foam mold with Plasti Dip, a flexible rubber coating that adheres well to EPS foam and provides waterproofing.

4. Paint and Seal: Paint the mold with waterproof paint and then seal it with a clear waterproof sealer to protect against moisture.

Each method has its strengths depending on your specific needs and the environment in which the EPS foam mold will be used.

Conclusion

Pouring water into an EPS foam mold is not only feasible but also advantageous for a variety of applications.

EPS foam’s properties, such as low water absorption, durability, and ease of molding, make it an ideal material for concrete casting, hydroponics, and artistic endeavors.

Whether you’re a construction professional, a hydroponic enthusiast, or an artist, EPS foam molds offer a versatile and reliable solution for your projects.

By understanding the interactions between water and EPS foam, you can harness the full potential of this material to achieve outstanding results.