Imagine shaping foam with the ease of slicing through warm butter, leaving behind a smooth, sealed, and perfectly precise edge.

No messy dust, no crushed granules, just a clean, professional finish. This is the magic of Cutting Foam Hot Wire.

Whether you’re a hobbyist building RC planes, a cosplayer crafting a detailed costume, a model maker constructing architectural landscapes, or an artist creating sculptures, a hot wire cutter is an indispensable tool.

It transforms a bulky, shapeless block of foam into intricate, complex forms with unparalleled ease.

The Science of Cutting Foam Hot Wire: How It Works

At its core, hot wire cutting is a thermal process, not a mechanical one. Unlike a blade that tears and crushes foam cells, a hot wire melts its way through.

The Principle:

A thin wire, typically made of Nichrome (a nickel-chromium alloy known for its high electrical resistance and ability to withstand extreme heat), is stretched taut between two points.

When an electrical current passes through this wire, its resistance causes it to heat up rapidly, reaching temperatures between 200°C and 500°C (400°F – 900°F).

As the heated wire comes into contact with the foam, it transfers heat so quickly that the plastic foam material at the point of contact instantly vaporizes.

This creates a narrow, clean kerf (the cut path) with a smooth, sintered surface that often requires no further sanding or finishing.

Key Advantage: The melting action seals the foam’s surface cells, resulting in a hard, glassy finish that is ideal for painting and detailing.

Step-by-Step Breakdown of the Working Principle

1. The Heating Element: The Wire Itself

The “hot wire” is typically made of a metal alloy with high electrical resistance, such as Nichrome (Nickel-Chromium) or sometimes stainless steel.

- Why High Resistance? When electric current flows through a conductor, the atoms of the conductor resist the flow of electrons. This resistance converts electrical energy into thermal energy (heat). A higher resistance means more heat is generated for the same amount of current.

- Why Nichrome? It has a high melting point (around 1400°C / 2550°F), so it can get very hot without melting or oxidizing (burning away) quickly.

2. The Power Source: Providing the Current

A low-voltage, high-current power source (like a variable AC/DC transformer or a dedicated power supply) is used.

- Low Voltage (Typically 1-12V): This is for safety, as the operator often works close to the wire.

- High Current (Several Amps): A substantial amount of current is needed to heat the wire to the required temperature (usually between 200°C and 400°C / 400°F and 750°F, depending on the foam).

3. The Cutting Action: Heat vs. Foam

When the hot wire comes into contact with the foam, the process is melting and vaporization, not burning.

- Thermal Transfer: The intense heat of the wire is transferred directly to the foam cells at the point of contact.

- Melting: The thermoplastic material (most commonly Expanded Polystyrene – EPS or Extruded Polystyrene – XPS) instantly melts.

- Vaporization: Due to the high temperature, a very thin layer of the molten plastic actually vaporizes into a gas. This is the small amount of smoke you see during cutting.

- Separation: The combination of melting and a tiny amount of vaporization creates a narrow kerf (the cut channel), separating the foam block into two pieces.

Foam Types: What You Can and CANNOT Cut

Generally SAFE to Cut (With Ventilation)

These are thermoplastics that melt and vaporize cleanly at hot wire temperatures.

Highly Recommended:

- Expanded Polystyrene (EPS)

- Common Names: Beadboard, White Foam, Packaging Peanuts.

- How it Cuts: Excellent. This is the ideal material for hot wire cutting. It cuts like butter, leaving a very smooth, hard surface. The beads melt away cleanly.

- Uses: Model making, prototypes, insulation boards, sculpting.

- Extruded Polystyrene (XPS)

- Common Names: Pink/Blue/Green Board (Dow Styrofoam™, Owens Corning Foamular™).

- How it Cuts: Very Good. Slightly denser than EPS, so it may require a slightly higher temperature/wire speed. It produces a smooth, fine-grained cut. A favorite for architectural models.

- Uses: Architectural models, terrain building, insulation.

Can Be Cut (With Caution):

- Polyethylene (PE) Foam

- Common Names: Packing foam, foam sheets, “Plastazote” (cross-linked PE).

- How it Cuts: Fair to Difficult. PE has a higher melting point and can be “stringy,” often leaving sticky residue on the wire that can burn. It requires a hotter wire and a slower, steady feed rate. Clean the wire frequently.

- Uses: Packaging, cosplay armor, flotation devices.

- Polypropylene (PP) Foam

- Common Names: Similar uses to PE foam.

- How it Cuts: Similar to PE. It can be cut but tends to be even more stringy and sticky than polyethylene. Not ideal for fine detail work.

DO NOT CUT – EXTREME TOXICITY HAZARD

These foams are thermosets or contain additives that, when heated, break down into highly toxic and corrosive chemicals. Cutting these with a hot wire is extremely dangerous.

- Polyurethane (PUR) – Especially Flexible Foam

- Common Names: Upholstery foam, couch cushions, mattress foam, pool noodles, spray foam insulation.

- The Danger: When heated, polyurethane releases Cyanide Gas and Isocyanates. These are extremely poisonous and can cause severe respiratory damage, neurological problems, or be fatal. The fumes are also highly irritating to the eyes and skin.

- Visual Clue: Often yellow, soft, and flexible. If you’re unsure, don’t cut it.

- Polyvinyl Chloride (PVC) Foam

- Common Names: Sintra / Forex / Komatex (rigid), Vinyl foam.

- The Danger: When heated, PVC releases Chlorine Gas and Dioxins. Chlorine gas was used as a chemical weapon in WWI. It attacks the respiratory system and is highly corrosive. The acid can also quickly degrade and break your Nichrome wire.

- Visual Clue: Often used in sign-making. It’s a dense, smooth, plastic-like sheet.

- Foams with Fire Retardants

- Common Names: Can be any foam type (including EPS/XPS) that is labeled “Fire-Rated,” “Flame-Resistant,” or “Class A.”

- The Danger: The chemical compounds used to make foam fire-resistant (often brominated or chlorinated compounds) become highly toxic when vaporized. They can release a cocktail of dangerous gases, including the same toxins as PVC.

- Rule of Thumb: If the foam is intended for construction or industrial use where fire code is a concern, assume it is fire-retardant and DO NOT CUT IT with a hot wire.

Types of Hot Wire Cutters

There are several types of cutters, each suited for different tasks and budgets.

1. Handheld Freehand Cutters (Hot Knives)

- Description: A handle with a wire loop or blade at the end, often battery-powered.

- Best For: Quick cuts, rough shaping, and trimming large blocks.

- Pros: Inexpensive, portable, great for basic tasks.

- Cons: Difficult to achieve straight, precise, or repeatable cuts.

2. Bench-Top Bows / Scroll Cutters

- Description: A U-shaped or C-shaped bow with a taut wire across the opening. The workpiece is manually pushed through the stationary wire.

- Best For: Making straight cuts, basic angles, and 2D shapes from sheet foam.

- Pros: Excellent for straight lines and curves, relatively affordable.

- Cons: Limited to the size of the bow’s opening.

3. 4-Axis Hot Wire Cutters (The “Lathe” Cutter)

- Description: A hybrid between a bow and a lathe. The foam rotates on one axis while the wire can move in and out, allowing for complex symmetrical shapes like propellers, vases, and aircraft wings.

- Best For: Creating radially symmetrical 3D objects.

- Pros: Opens up a world of 3D shapes without a CNC machine.

- Cons: Can be complex to set up and operate.

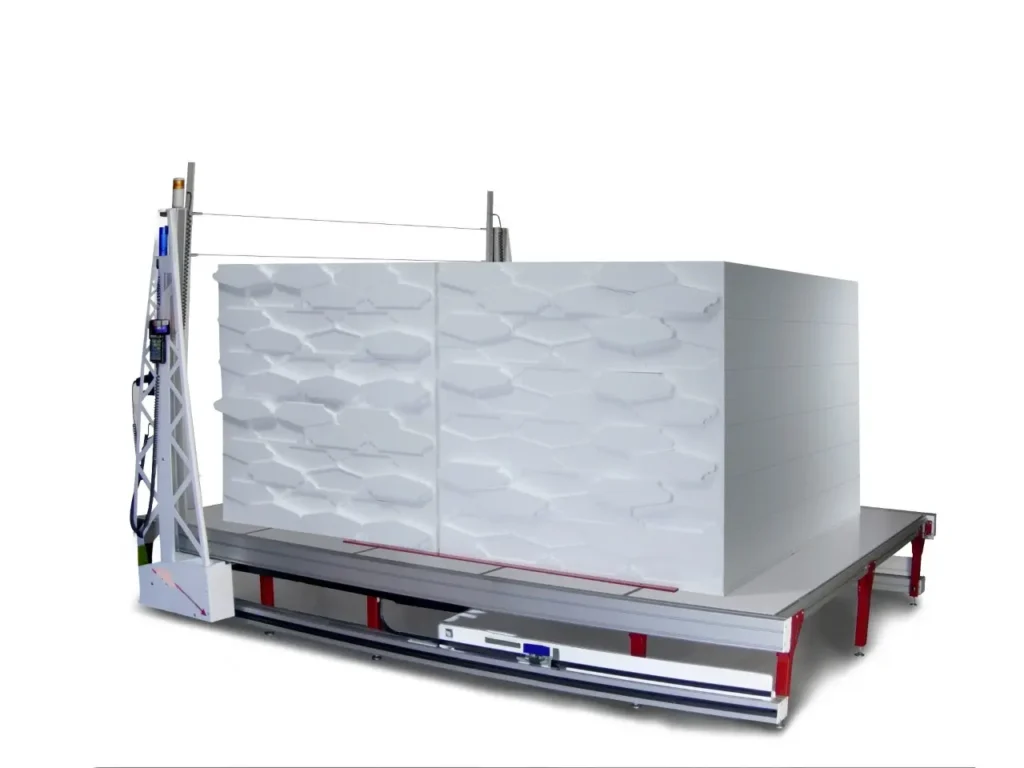

4. CNC Hot Wire Cutters

- Description: A computer-controlled machine that moves the wire (or the foam) along multiple axes to create incredibly complex 3D shapes with high precision and repeatability.

- Best For: Professional prototyping, architectural models, and production work.

- Pros: Ultimate precision, perfect for complex or repetitive tasks.

- Cons: Very expensive; requires CAD/CAM software and knowledge.

Building Your Own DIY Cutting Foam Hot Wire

Building a simple bench-top bow cutter is a rewarding and cost-effective project. Here’s how to do it.

Materials Needed:

- Wood: For the base and the uprights of the bow.

- Nichrome Wire: 22-28 AWG gauge is a good starting point. (The longer the wire, the thicker it should be).

- Power Source: A 12V DC power supply (like an old laptop charger) is ideal. It’s safe and provides ample power. Avoid using mains power (120V/240V) directly—it is extremely dangerous.

- Springs: Two small extension springs to keep the wire taut as it heats and expands.

- Electrical Components: Alligator clips, screws, and wires.

- Fuse: A 5-10 Amp in-line fuse is CRITICAL for safety to prevent overheating.

Step-by-Step Build Guide:

- Build the Bow: Construct a U-shaped frame from wood. The height and width will determine the maximum size of foam you can cut.

- Attach Terminals: Install two screws at the top of each upright. Connect one spring to each screw.

- Wire the Power: Connect one wire from your power supply’s positive (+) terminal to one of the screws. Connect the other wire from the negative (-) terminal to the fuse, and then connect the fuse to the other screw.

- String the Wire: Cut a length of Nichrome wire and attach it to the springs using alligator clips or by wrapping it tightly. The springs will maintain tension.

- Test and Adjust: Turn on the power supply. The wire should glow a dull orange-red. If it doesn’t heat up, your wire may be too thick or your power supply too weak. If it glows bright red and snaps, it’s too hot—use a lower voltage or a thicker wire.

Congratulations! You now have a functional hot wire cutter.

Mastering the Cut Techniques and Tips

Having the right tool is only half the battle. Technique is everything.

The Golden Rule: Speed and Temperature

Finding the perfect balance between wire temperature and cutting speed is the key to a perfect cut.

- Too Slow + Too Hot: The wire overheats the foam, creating a wide kerf, deep burn marks, dips, and an uneven surface.

- Too Fast + Too Cool: The wire doesn’t melt the foam cleanly, causing drag lines, snagging, broken wires, and a rough, stringy finish.

- The Perfect Cut: You should hear a soft “hiss” and smell a faint, waxy odor. The cut surface will be smooth and glossy. The foam should offer almost no resistance.

Advanced Cutting Techniques

- Using Jigs and Guides: For straight cuts, never rely on freehand. Clamp a straight piece of wood or metal to use as a guide for your foam block. This ensures perfectly straight, repeatable edges.

- Cutting Complex 2D Shapes:

- Print your design on paper and glue it directly onto the foam sheet.

- Carefully follow the lines with your handheld cutter or bow, keeping the wire perpendicular to the foam.

- Creating 3D Shapes:

- Stack Slicing (The “Topographic” Method): This is the most common method. Use 3D slicing software (or simply draw contours by hand) to create cross-sectional templates. Print these templates, glue them to individual foam sheets, cut them out with your bow cutter, and then stack and glue the layers together to form the final 3D shape.

- The Drag Knife Method (For Bows): Attach a metal pin to a block that holds the hot wire. This pin follows the edge of a template, while the hot wire, offset from the pin, cuts the foam. This is excellent for producing multiple identical 2D parts.

Safety Precautions

Working with a hot wire and melted plastic requires respect for safety.

- VENTILATION: This is the most important rule. Always work in a well-ventilated area. Use a fume extractor or a fan to blow fumes away from you. The vapors from melted polystyrene are styrene gas, which is an irritant and harmful with prolonged exposure.

- Fire Hazard: The hot wire is extremely hot and the foam is flammable. Never leave a powered cutter unattended. Keep it away from other flammable materials and have a fire extinguisher nearby.

- Electrical Safety: If building your own, ensure all connections are secure and insulated. Never use a power source that isn’t electrically isolated, like a simple transformer. Your 12V laptop charger is safe; a variable AC supply is not.

- Toxic Fumes Reminder: NEVER CUT POLYURETHANE, POLYISOCYANURATE, OR PVC FOAMS.

- Personal Protective Equipment (PPE): Safety glasses are essential to protect your eyes from unexpected splatter. A simple dust mask can help with minor fumes, but it is not a substitute for proper ventilation.

Conclusion

Cutting Foam Hot Wire is a skill that unlocks limitless creative potential. It bridges the gap between rough ideas and refined, tangible objects.

From the simple DIY bow to sophisticated CNC machines, this technology empowers makers to shape their visions with precision and efficiency.

Start with a block of safe XPS foam, practice controlling your speed and temperature, and master the fundamental cuts.