In today’s fast-moving industrial and consumer markets, packaging solutions need to be lightweight yet durable, cost-effective yet sustainable.

Expanded Polypropylene (EPP) foam boxes have emerged as a superior alternative to traditional packaging materials like EPS (Styrofoam), cardboard, and plastic.

EPP foam boxes offer:

Exceptional impact resistance – Protects fragile items better than most alternatives

Superior thermal insulation – Ideal for temperature-sensitive shipments

100% recyclable – Environmentally friendly compared to single-use plastics

Reusable design – Can withstand multiple shipping cycles

Whether you’re in e-commerce, food logistics, or medical supplies, understanding EPP foam boxes can help you reduce damage rates, lower shipping costs, and improve sustainability.

What is EPP Foam?

Expanded Polypropylene (EPP) is a closed-cell bead foam manufactured through a unique steam molding process. Unlike EPS (Styrofoam), EPP has:

- Higher density-to-strength ratio (20-200g/L options)

- Elastic memory – Returns to shape after compression

- Chemical resistance – Won’t degrade from oils or solvents

- Temperature stability (-40°C to 130°C operating range)

EPP vs. Common Packaging Materials

| Property | EPP Foam | EPS Foam | Corrugated Cardboard | Plastic Cases |

|---|---|---|---|---|

| Impact Resistance | ★★★★★ | ★★★☆ | ★★☆ | ★★★★ |

| Thermal Insulation | ★★★★★ | ★★★★ | ★☆ | ★★ |

| Moisture Resistance | ★★★★★ | ★★★ | ★ | ★★★★ |

| Reusability | ★★★★★ | ★★ | ★ | ★★★ |

| Eco-Friendliness | ★★★★☆ | ★★ | ★★★ | ★☆ |

How EPP Foam Works (Functional Mechanism)

Impact Absorption: When compressed, the air pockets collapse progressively, absorbing energy.

Shape Recovery: Unlike EPS (styrofoam), EPP bounces back after impact (elastic memory).

Thermal Insulation: Air pockets reduce heat transfer.

Vibration Damping: Absorbs vibrations (used in automotive parts).

Applications of EPP Foam

A. Automotive Industry

Bumpers, dashboards, seat cushions (absorbs crash energy).

Battery casings for EVs (lightweight & heat-resistant).

B. Packaging

Electronics (e.g., drones, laptops) – Protects against drops.

Medical equipment – Sterilizable and shock-absorbent.

C. Sports & Safety

Bicycle helmets, knee pads – Lightweight protection.

Playground surfaces – Soft yet durable.

D. Construction

Insulation panels – Thermal & soundproofing.

Advantages of EPP Foam

Lightweight but strong (better strength-to-weight ratio than EPS).

Reusable & recyclable (eco-friendly alternative to styrofoam).

Chemical & water-resistant (won’t degrade easily).

Good thermal insulation (used in food packaging).

Disadvantages

More expensive than EPS (but longer-lasting).

Requires specialized molding equipment.

How EPP Foam Boxes Are Manufactured

1. Mold Design & Fabrication

- CAD models are created based on box dimensions

- Aluminum molds are CNC-machined for precision

- Complex designs may use multi-part molds with sliding cores

2. Bead Pre-Expansion

- Raw EPP pellets are expanded using steam at 100-120°C

- Density is controlled (typically 30-100g/L for boxes)

- Beads stabilize for 6-24 hours before molding

3. Steam Chest Molding Process

- Expanded beads are loaded into the mold cavity

- Steam at 1-3 bar pressure fuses beads together

- Water cooling solidifies the structure (~2-5 min cycle time)

4. Post-Processing

- Trimming excess material with hot wire cutters

- Adding anti-static coatings (for electronics)

- Printing/logos via pad printing or labels

How to get EPP Foam Box Mold

Core design stage

3D modeling specifications

Use SolidWorks/UG for mold splitting design

Key parameter settings:

Demolding angle ≥1.5° (2-3° for deep cavity structure)

Wall thickness tolerance ±0.15mm

Steam hole layout: staggered arrangement, hole diameter 1.0±0.1mm

Must include:

Vacuum adsorption groove (3mm wide and 2mm deep)

Rapid cooling water channel (8-10mm from the cavity surface)

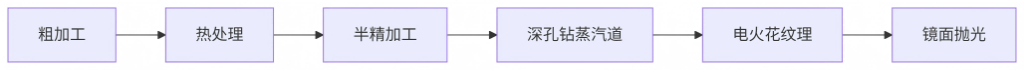

Precision machining process

Material selection comparison table

Material Hardness HRC Thermal conductivity (W/mK) Applicable scenarios

6061 aluminum alloy 25 167 Prototype verification mold

H13 mold steel 52 24.3 500,000 times mass production mold

Beryllium copper alloy 38 105 High heat dissipation area inserts

CNC machining key steps

Core component machining accuracy

Parting surface flatness: ≤0.02mm/m²

Ejector hole matching: H7/g6 grade

Cavity surface roughness: Ra≤0.4μm

Key points of mold trial debugging

First sample inspection items

Density deviation: ≤±3% (weighing method)

Dimension qualification rate: ≥95% (3D scanning comparison)

Demolding force test: ≤2kN (pressure sensor monitoring)

Key Benefits of Using EPP Foam Boxes

1. Protective Qualities

- 95%+ reduction in shipping damage vs cardboard

- Can withstand 50+ drops from 1m height (tested per ISTA 3A)

2. Temperature Control Performance

- Maintains internal temps 5x longer than EPS

- FDA-compliant for food and pharmaceutical use

3. Sustainability Advantages

- 100% recyclable through EPP recovery programs

- Reusable 50+ times before recycling needed

4. Customization Flexibility

- Molded inserts for product-specific cushioning

- Branded colors (Pantone matching available)

EPP Sheets Step by Step Manufacturing Process

Step 1: Pre-Expansion (Bead Foaming)

- Feeding raw beads – Polypropylene beads are loaded into a pre-expander.

- Heating with steam – Steam at 100–120°C softens the beads while the blowing agent (pentane) causes them to expand.

- Controlled expansion – Beads grow 20–50 times their original size, forming small closed-cell foam beads.

Step 2: Stabilization & Conditioning

- Drying – Expanded beads are dried to remove moisture.

- Aging – Stored for 4–24 hours to stabilize internal pressure.

Step 3: Molding into Sheets

- Filling the mold – Expanded beads are loaded into a flat-press mold.

- Steam heating – Steam is injected to fuse the beads together.

- Cooling & demolding – The mold is cooled with water, and the fused EPP sheet is removed.

Step 4: Post-Processing (Optional)

- Cutting & trimming – Sheets are cut to desired thickness and dimensions.

- Laminating – Additional layers (films, fabrics) can be bonded for enhanced properties.

- Surface treatment – Coating or printing for aesthetics or functionality.

Key Equipment for EPP Foam Sheet Production

| Equipment | Purpose |

|---|---|

| Pre-expander | Expands PP beads using steam and blowing agents. |

| Molding machine | Fuses beads into sheets under heat and pressure. |

| Steam generator | Provides steam for expansion and molding. |

| Hydraulic press | Ensures uniform thickness and density. |

| Cutting machine | Trims sheets to final dimensions. |

Quality Control & Testing

To ensure high-quality EPP foam sheets, manufacturers conduct:

- Density testing – Verifies weight-to-volume ratio.

- Compression resistance – Measures load-bearing capacity.

- Thermal stability – Checks heat resistance and insulation properties.

- Dimensional accuracy – Ensures uniform thickness and flatness.

Applications of EPP Foam Sheets

- Automotive – Door panels, bumpers, and impact absorbers.

- Packaging – Protective inserts for electronics and fragile goods.

- Toys & sports – Lightweight, safe materials for toy airplanes, helmets, etc.

- Construction – Insulation panels for walls and roofs.

Advantages Over Other Foams (EPS, EPE, PU)

| Feature | EPP | EPS | EPE | PU Foam |

|---|---|---|---|---|

| Impact resistance | Excellent | Brittle | Good | Moderate |

| Recyclability | Yes | Limited | Yes | No |

| Heat resistance | High | Low | Low | High |

| Flexibility | High | Rigid | High | High |

Conclusion

EPP foam boxes deliver unmatched protection, sustainability, and long-term value for companies that:

Ship high-value or fragile items

Need temperature-controlled solutions

Want to reduce environmental impact

Next Steps:

- Request samples from EPP manufacturers

- Conduct real-world shipping tests

- Calculate total cost of ownership vs current packaging

For most businesses, the switch to EPP pays for itself within 6-18 months through damage reduction and reuse savings.