What is EPS Mold

EPS molding, the full name of which is Expanded Polystyrene Molding, refers to the process of expanding polystyrene particles through specific processes and equipment to form products with specific shapes and properties.

EPS Mold Principle

In the EPS molding process, polystyrene particles are first heated to a certain temperature to volatilize the foaming agent inside them and the particles begin to expand.

Subsequently, in the mold, the expanded particles fuse with each other and fill the mold space, and after cooling and solidification, they finally form the desired shape.

The principle of EPS molding is based on the physical properties and thermoplastic characteristics of polystyrene.

Heating intensifies the movement of the molecular chains inside the particles, and the gas generated by the volatilization of the foaming agent causes the particles to expand.

The shape and size of the mold determine the appearance and size of the final molded product.

This molding method has many advantages, such as the ability to produce lightweight, good thermal insulation and excellent cushioning products.

At the same time, by adjusting process parameters such as heating temperature, amount of foaming agent, mold temperature, etc., the density, strength and other performance indicators of the product can be controlled.

Understanding the basic concepts and principles of EPS molding is essential for further mastering its application and optimizing the production process.

It provides a theoretical basis for the rational use of EPS molding technology in different fields.

Molding steps

Material preparation

The raw materials for EPS molding mainly include polystyrene beads, foaming agents, stabilizers, pigments, etc.

Polystyrene beads should be selected with stable quality and high purity. Before use, the raw materials need to be screened and processed to remove impurities and particles that do not meet the requirements.

The material formulation needs to accurately control the proportion of each component according to the performance requirements of the specific product.

For example, the amount of foaming agent added will directly affect the foaming effect and the density of the product.

Select the appropriate type of EPS foam based on project’s needs.

EPS foam comes in various densities and thicknesses. Higher-density foam is more rigid and durable, while lower-density foam is lighter and easier to shape.

Mold design and manufacturing

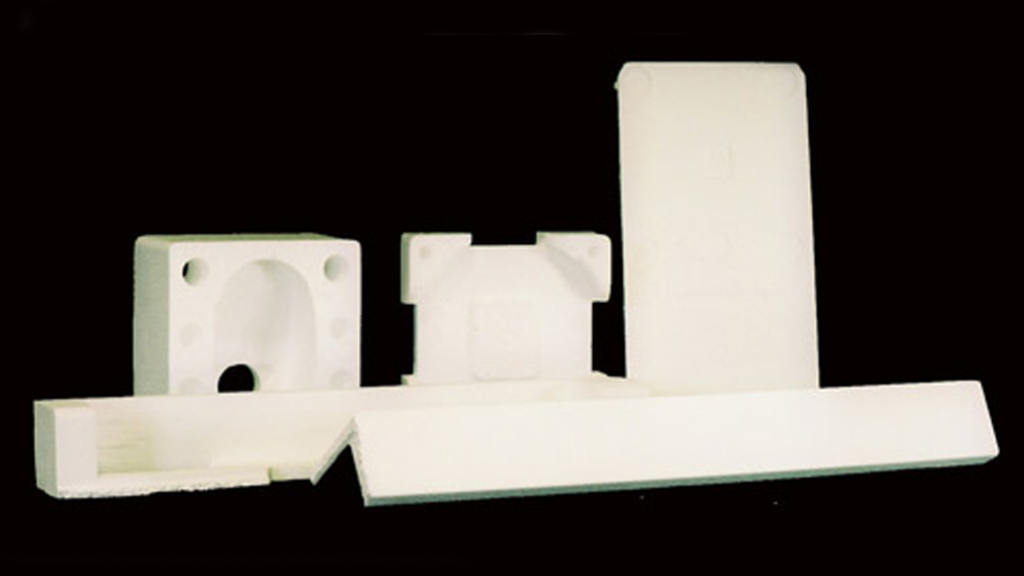

The mold is crucial in EPS molding. Common mold types include standard molds and flat molds. The mold structure usually consists of a mold frame and a cavity.

The mold frame includes a concave mold frame and a convex mold frame, and the size needs to be standardized to facilitate the installation and replacement of the cavity.

The cavity is composed of a concave mold, a convex mold, a panel and a back plate, and its geometric shape is directly related to the shape of the product.

The mold manufacturing process has high requirements, and generally uses materials such as aluminum sand castings, stainless steel or bronze.

The thermal conductivity, corrosion resistance and long-term stability of the mold should be considered during the manufacturing process.

The surface of the final product may need to be sanded or polished to achieve the desired finish.

Molding process

Heating: Put the pre-expanded beads into the mold and heat them quickly through steam heating.

The general heating time is about 20-60 seconds, and the temperature is controlled between 100-130℃.

Injection: While heating, inject the molten material into the mold cavity to ensure that the material is evenly distributed.

Cooling: Water cooling or vacuum cooling methods are commonly used. Water cooling can make the product surface smooth and increase strength; vacuum cooling time is shorter.

The cooling time needs to be determined experimentally based on the characteristics of the mold and product, usually ranging from a few minutes to more than ten minutes.

Demolding: Use compressed air to blow the product to one side of the fixed mold, and then use a mechanical ejector to eject the product from the mold.

During the demolding process, if mold sticking is found, the mold should be heated and a release agent should be applied before the next cycle.

Common Problems and Solutions

Common Problems

In the process of EPS molding, several common challenges often arise. One of the significant issues is material inconsistency.

The quality and properties of the polystyrene particles can vary, affecting the uniformity and performance of the final product.

Poor quality particles may lead to inconsistent expansion and result in products with uneven density and strength.

Another challenge is the difficulty in achieving precise control of the molding process.

Variations in heating temperature, the duration of heating, and the speed of injection into the mold can all impact the final shape and properties of the EPS product.

Imperfect mold design can also cause problems such as incomplete filling or uneven cooling, leading to defects in the molded part.

Effective Solutions

To address the challenge of material inconsistency, it is crucial to source high-quality polystyrene particles from reliable suppliers.

Regular quality checks and material testing can help ensure the consistency and quality of the raw materials.

For precise control of the molding process, advanced temperature control systems and accurate injection mechanisms should be employed.

Implementing real-time monitoring and feedback systems can allow for immediate adjustments to process parameters to achieve the desired results.

In terms of mold design, thorough simulation and analysis using computer-aided design (CAD) and mold flow analysis software can optimize the mold structure.

This helps ensure uniform filling and cooling, reducing the occurrence of defects.

Furthermore, continuous training and skill development of the operating personnel are essential to ensure they have the knowledge and expertise to handle the molding process effectively and troubleshoot any issues that arise promptly.

Techniques and Tips

Molding Techniques

Injection molding is a common EPS molding technology that manufactures products by injecting molten polystyrene material into a mold.

This technology can produce products with complex shapes and has relatively high production efficiency.

In injection molding, precise control of injection pressure, speed and temperature is essential to ensure that the material fills the mold evenly and reduces the occurrence of defects.

Compression molding is to place the preheated polystyrene material in the mold and then apply pressure to shape it.

This technology is suitable for producing larger size and thicker wall products, and can provide better material distribution and uniform density.

In addition, there is extrusion molding technology, which extrude polystyrene material into a profile of a specific shape, and then carry out subsequent processing and molding.

Practical Tips for Success

When performing EPS molding operations, some practical tips and precautions can significantly improve the molding effect.

First, ensure that the mold is clean and well-maintained to avoid impurities and wear that may affect product quality.

When heating polystyrene pellets, temperature uniformity is critical to prevent localized overheating or underheating.

The amount of foaming agent added must be controlled accurately. Too much or too little may lead to poor product performance.

The pressure and speed parameters during operation also need to be optimized and adjusted according to specific product requirements.

In addition, pay attention to the impact of environmental humidity on the molding process to avoid the material absorbing moisture and affecting the molding effect.

At the same time, be careful when demoulding to prevent product damage.

Advanced Methods

Innovative Approaches

In recent years, there have been several innovative approaches in EPS molding that are transforming the industry.

One such approach is the use of 3D printing technology in combination with EPS molding.

Another innovative method is the application of nanotechnology to enhance the properties of EPS materials.

Nanoparticles can be incorporated into the polystyrene to improve its strength, thermal insulation, and fire resistance.

Also, the development of multi-material molding techniques is gaining momentum.

By combining EPS with other materials like fiberglass or carbon fibers, products with enhanced mechanical properties can be produced.

This opens up new possibilities in areas such as automotive and aerospace where lightweight and high-strength components are in demand.

Conclusion

As an important production technology, EPS molding covers many aspects from basic principles to advanced methods.

Key points include: grasping the physical properties and thermoplastic characteristics of polystyrene to achieve effective heating expansion and mold filling;

adjusting product performance by precisely controlling process parameters such as temperature, pressure and foaming agent dosage;

and continuously optimizing mold design and selecting appropriate molding technology to meet different product requirements.

In this evolving field, continuous learning and innovation are essential.

The application of new technologies such as 3D printing, nanotechnology and multi-material molding has brought more possibilities to EPS molding.

At the same time, the pursuit of sustainability and intelligent production will also drive the continuous progress of the industry.

Continuous learning allows us to keep up with the latest research results and technological developments, apply them to actual production in a timely manner, and improve product quality and production efficiency.

Innovation can open up new markets and meet the increasingly diverse and high-standard customer needs.

In short, only by maintaining an attitude of learning and innovation can we achieve long-term success in the field of EPS molding and make greater contributions to the development of related industries.