Injection molding stands as one of the most versatile and widely used manufacturing processes globally, responsible for producing everything from microscopic medical components to massive automotive parts.

At the heart of this transformative process lies mold design—a complex, multidisciplinary engineering practice that determines not only the quality of the final product but also the efficiency, cost-effectiveness, and longevity of the manufacturing process itself.

Proper mold design transcends mere part shaping; it encompasses material science, thermodynamics, structural mechanics, and production planning.

A well-designed mold ensures dimensional accuracy, consistent quality, and economical production, while a poorly designed mold can lead to countless production issues, defective parts, and costly downtime.

This guide explores the fundamental principles, key components, and advanced considerations of injection mold design, providing manufacturers, engineers, and designers with the knowledge needed to optimize their molding operations.

What Is Injection Mold?

The Simple Analogy: A Waffle Iron

Think of a waffle iron. You pour batter (liquid material) into the iron (the mold), close it, and apply heat and pressure. After a short time, you open it to reveal a perfectly shaped, detailed waffle (the part).

An injection mold is a highly sophisticated, precision version of a waffle iron, designed for mass-producing plastic parts.

The Formal Definition

An injection mold (or mould) is a hardened steel or aluminum tool, machined to precise specifications, that is used in the injection molding process to mass-produce identical plastic parts.

It is not the machine itself, but the custom-designed tool that is inserted into the injection molding machine. A single machine can use many different molds to produce many different parts.

The Importance of Mold Design in Injection Molds

Determines the Quality of the Final Product

Mold design directly determines whether the molded part meets dimensional, aesthetic, and functional requirements.

Aesthetics: The location and type of the gate determine whether noticeable marks will be left on the part surface.

The design of the parting line determines the location and visibility of flash. Poor venting can lead to air traps, causing burning or short-shot fill.

Dimensional Accuracy & Stability: The design of the cooling system determines the cooling rate and shrinkage rate of different parts of the part.

Uneven cooling can lead to warpage, sink marks, and internal stress, resulting in dimensional deviations or product deformation.

Structural Integrity: The flow of molten plastic within the mold affects molecular orientation, thereby affecting the mechanical strength of the part. Weld lines located in high-stress areas can significantly weaken the part.

Control Production Costs and Efficiency

Mold design is the most significant factor affecting unit cost.

Cycle Time: Cooling time accounts for over 70% of the injection molding cycle.

An optimally designed cooling system can significantly reduce cooling time, thereby improving production efficiency.

Every second saved in cycle time translates into significant cost savings in high-volume production.

Material Utilization: The design of the runner and gating system determines how much material from each shot forms the product and how much becomes sprues and runners that need to be recycled or discarded.

Hot runner system design can achieve nearly 100% material utilization.

Mold Manufacturing Cost: The design determines the mold’s complexity, the amount of steel required, the machining time, and the assembly difficulty.

A clever design can achieve complex functions with a simple structure, while an ill-conceived one can result in a cumbersome mold structure, high costs, and a high failure rate.

Ensure Production Feasibility and Stability

Mold design must ensure smooth and repeatable product production.

Ejection: The design must ensure smooth and damage-free ejection of cured parts.

This involves the draft angle, ejector pin placement, and ejector pin design. Improper design can result in ejection defects, ejection punch-through, or part deformation.

Handling Complex Structures: For parts with undercuts or threads, mold design requires mechanisms such as slides and lifters to facilitate ejection.

The design of these motion mechanisms directly impacts mold function and life.

Venting: Air in the mold cavity must be effectively vented during plastic filling.

Poor venting can lead to defects such as filling difficulties, burning, and short shots. The location and depth of the vent grooves require precise design.

Mold Life and Maintenance: Robust design can significantly improve mold durability and reduce downtime for maintenance.

A Bridge Between Product Design and Manufacturing

Mold designers serve as a bridge between product designers and manufacturing engineers.

Design for Manufacturability (DFM): Excellent mold designers will intervene in product design early in the design process, suggesting modifications to make the product design more manufacturable, thereby preventing future production problems and increased costs.

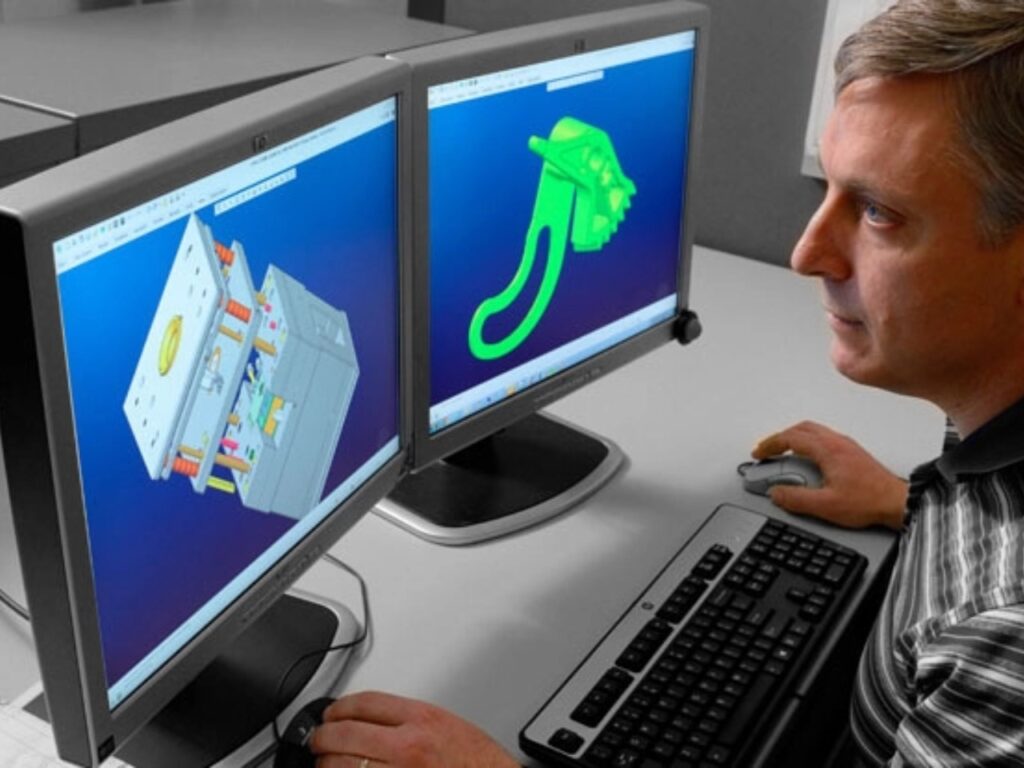

Problem Forecasting and Resolving: Using Mold Flow Analysis software, designers can simulate the plastic filling, holding pressure, cooling, and shrinkage processes within the mold before mold creation.

This allows them to predict and resolve potential problems such as warpage, shrinkage, and weld marks, significantly reducing mold trial costs and risks.

What is Injection Mold Design?

Injection mold design is the systematic process of creating detailed plans and specifications for the tool that will shape molten plastic into a desired form. It involves designing a precision tool that can:

- Withstand repeated cycling of high pressure and temperature

- Efficiently dissipate heat

- Facilitate the easy removal of finished parts

- Accommodate material shrinkage and behavior

- Enable maintenance and repair

- Ensure operator safety

The mold design process typically begins after product design is finalized and involves close collaboration between product designers, mold designers, material scientists, and manufacturing engineers.

The Injection Mold Design Process: A Step-by-Step Overview

1. Part Analysis and DFM (Design for Manufacturability)

The first critical step involves thoroughly analyzing the part design for manufacturability. During this phase, engineers:

- Identify potential molding issues (undercuts, thin walls, etc.)

- Determine optimal parting lines

- Suggest design modifications to improve moldability

- Analyze draft angles, wall thickness, and rib design

- Consider material selection and its impact on mold design

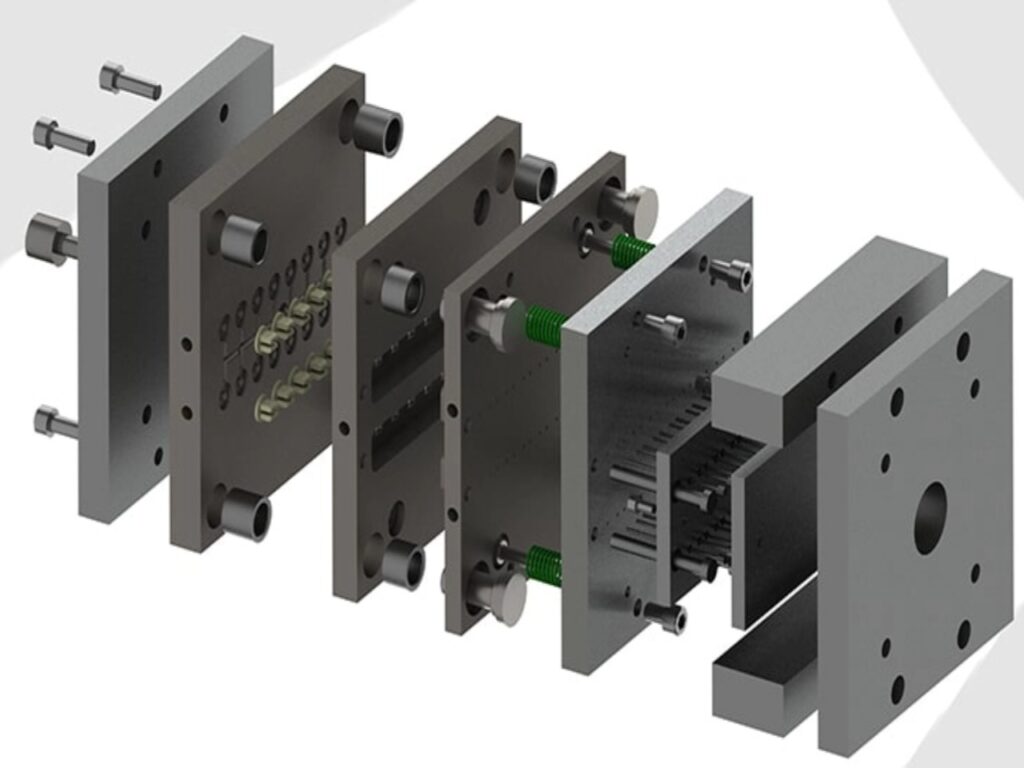

2. Mold Type Selection

Based on part requirements, designers select the appropriate mold type:

- Two-plate molds: simplest and most common

- Three-plate molds: for automatic runner separation

- Hot runner molds: for high-volume production

- Stack molds: for increased production capacity

- Family molds: for producing multiple different parts

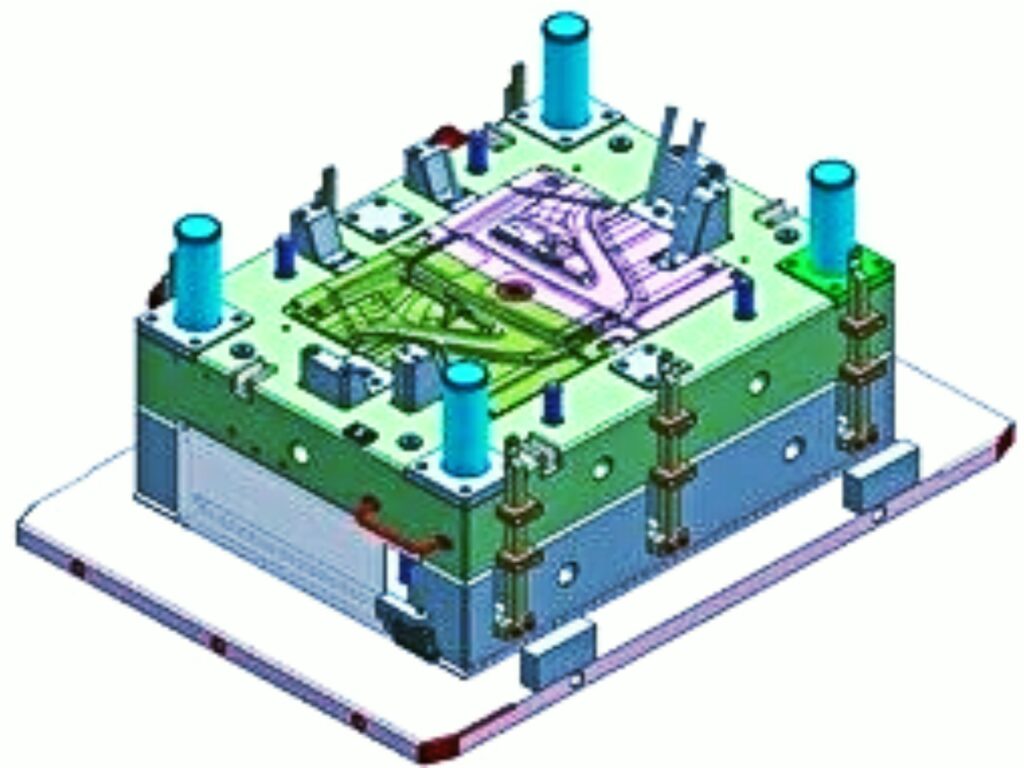

3. Cavity and Core Design

This phase involves creating the heart of the mold—the cavities and cores that form the part:

- Determining the number of cavities based on production requirements

- Designing the cavity and core blocks

- Planning the surface finishes and textures

- Incorporating necessary certifications and standards

4. Feed System Design

The feed system controls how material flows into the mold:

- Sprue design: connecting the machine nozzle to the mold

- Runner design: balancing flow to multiple cavities

- Gate design: controlling how material enters the cavity

- Hot runner systems: for reduced waste and improved efficiency

5. Cooling System Design

Perhaps the most critical aspect affecting cycle time and part quality:

- Cooling channel layout and sizing

- Considerations for different mold materials

- Baffles, bubblers, and thermal pins for hard-to-cool areas

- Connection to mold temperature control units

6. Ejection System Design

Planning how finished parts will be removed from the mold:

- Ejector pin placement and sizing

- Stripper plates, sleeves, and blades

- Return mechanisms and safety features

- Air ejection systems for delicate parts

7. Venting System Design

Proper venting is essential for part quality:

- Placement of ventilation channels

- Depth calculations based on material viscosity

- Alternative venting methods (ejector pin vents, porous metals)

8. Structural Components Design

Ensuring the mold can withstand injection pressures:

- Plate thickness and strength calculations

- Support pillar placement

- Guide pin and bushing selection

- Clamping requirements

9. Finalization and Documentation

Creating comprehensive documentation for mold manufacturing:

- Detailed drawings with tolerances

- Material specifications

- Surface treatment requirements

- Assembly instructions

Key Principles of Effective Mold Design

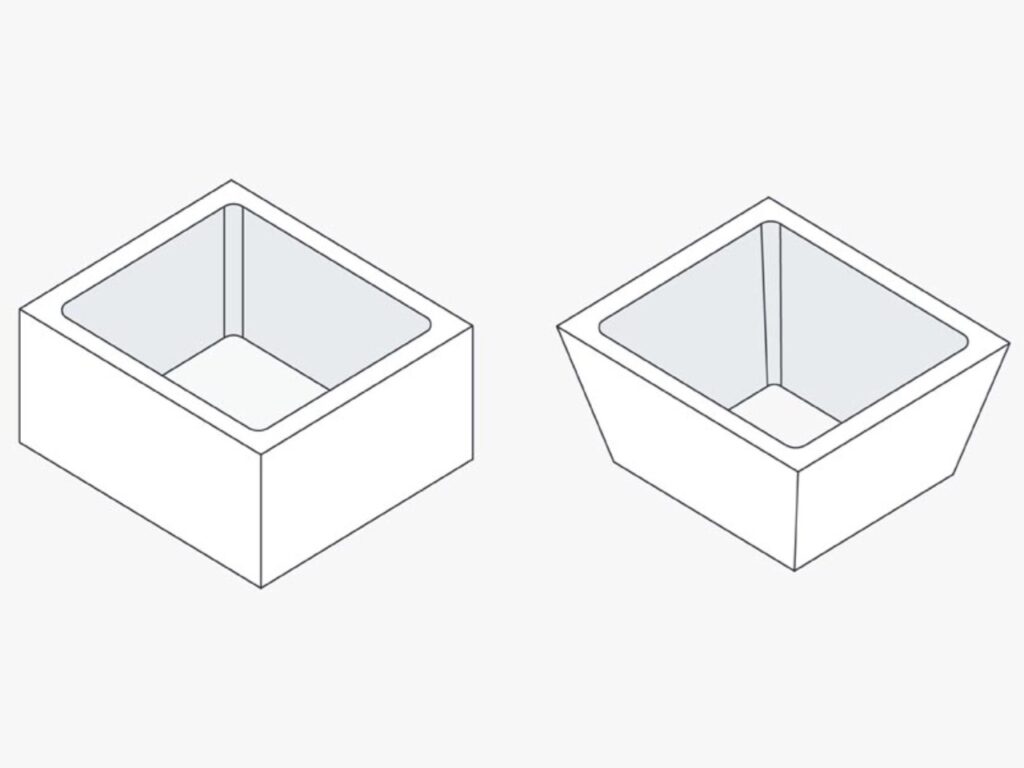

1. Parting Line Selection

The parting line represents where the two mold halves meet and separate. Its placement affects:

- Part appearance and flash formation

- Ejection mechanism design

- Mold construction complexity

- Dimensional accuracy

2. Gate Location and Type

Gate design significantly impacts part quality:

- Edge gates: most common, easy to manufacture

- Tab gates: reduce shear stress on parts

- Pinpoint gates: small marks, good for appearance

- Submarine gates: automatic degating

- Diaphragm gates: for cylindrical parts

- Fan gates: for wide, thin parts

3. Cooling System Efficiency

An efficient cooling system provides:

- Reduced cycle times (up to 30-40% improvement)

- Consistent part dimensions

- Reduced internal stresses

- Improved surface quality

4. Venting Effectiveness

Proper venting prevents:

- Burn marks from trapped air

- Incomplete filling

- Weak weld lines

- Surface defects

5. Ejection System Design

An effective ejection system ensures:

- Reliable part removal without damage

- Consistent cycle times

- Minimal maintenance requirements

- Operator safety

Advanced Considerations in Modern Mold Design

1. Moldflow Analysis and Simulation

Computer-aided engineering (CAE) tools allow designers to:

- Predict filling patterns and potential issues

- Identify weld lines and air traps

- Optimize gate locations

- Predict cooling efficiency

- Anticipate warpage and shrinkage

2. Rapid Tooling Technologies

Advances in manufacturing have enabled:

- Conformal cooling channels via 3D printing

- Reduced lead times through rapid prototyping

- Hybrid molds combining different manufacturing methods

- Advanced surface treatments for extended mold life

3. Multi-Material and Overmolding

Complex molds designed for:

- Multiple materials in single cycle

- Soft-touch over rigid substrates

- Integrated seals and gaskets

- Combined colors and textures

4. Micro-Molding Design

Special considerations for microscopic parts:

- Ultra-precision machining requirements

- Specialized ejection systems

- Unique venting solutions

- Extreme tolerance considerations

5. Sustainable Design Practices

Environmentally conscious mold design:

- Energy-efficient cooling systems

- Materials with longer lifecycles

- Designs that minimize material waste

- Compatibility with recycled materials

Conclusion

Injection mold design represents a critical intersection of art and science, where technical expertise meets creative problem-solving.

The difference between a good mold and a great mold can mean the difference between profitability and loss, between quality products and defective ones, between efficient production and constant troubleshooting.

As manufacturing technologies continue to advance, the role of the mold designer becomes increasingly complex and important.

By understanding the fundamental principles, embracing new technologies, and following best practices, mold designers can create tools that not only produce high-quality parts but also drive innovation in manufacturing.

The most successful mold designs emerge from collaboration, experience, and a willingness to embrace both established principles and new technologies.

In the constantly evolving world of injection molding, the mold design process remains the foundation upon which successful manufacturing is built.