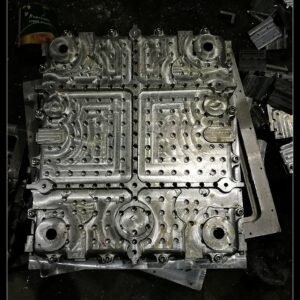

EPS mold

Showing 1–16 of 21 results

-

Architectural Styrofoam Molding

Read more -

Customized Eps Expandable Polystyrene Heart Shape Box Mold

Read more -

Customized Processing EPS Dates Box Mold For Fruit Box Vegetable Box

Read more -

Direct supply eps mold is used to make fish box

Read more -

EPS Aluminium Mould For Electrical Package and Concrete Wall

Read more -

EPS ICF Mould Decorative Molding For Shape Moulding Machine

Read more -

EPS lost foam mold

Read more -

EPS Mold For Foam Fish Box

Read more -

EPS Mold Packaging Inject Mould For Shape Moulding Machine

Read more -

EPS Packaging Box Foam Mould Full Mould Casting

Read more -

Expandable Polystyrene Foam Box EPS Helmet Mold

Read more -

Foam Crown Molding

Read more -

Highly Customized EPS Molds for Helmet Molds

Read more -

Injection Molded Eps Foam Product Aluminum Mould For Household Appliances Packing

Read more -

Insert Molds For Concrete Walls EPS Heat Insulation Concrete Board panel Mold

Read more -

Lightweight Eps Concrete Foam Block Mold Eps Fish Box Injection Mold

Read more