What is Foam Casting Molds

Foam casting molds occupy an important position in the manufacturing industry.

Their application range is wide, covering the fields of daily necessities such as automobile, aerospace and other transportation vehicles, and electronic products and medical devices.

In automobile manufacturing, foam molds can be used to manufacture interior parts, seat pads, door panels and dashboards.

For example, in the manufacture of car seat pads, foam molds can accurately shape ergonomic shapes to provide a comfortable riding experience.

At the same time, they can also provide shock absorption protection in the event of a collision to improve the safety of riding.

In the field of electronic product manufacturing, foam molds are used to manufacture the internal packaging of electronic products to ensure the safety of products during transportation and storage.

For example, for mobile phone packaging, foam molds can be customized according to the shape and size of the mobile phone to provide good protection.

In medical device manufacturing, foam molds are used to manufacture packaging for high-value medical devices and instruments.

These molds ensure that medical devices are not damaged during transportation and use, and help maintain cleanliness and hygiene.

The manufacture of foam casting molds involves multidisciplinary knowledge, including materials science, mechanical engineering, computer-aided design, etc.

The design process is complex and needs to consider factors such as the shape, size, and precision requirements of the product.

At the same time, the manufacturing difficulty is also high, requiring advanced processing equipment and technology.

In short, foam casting molds play an important role in the manufacturing industry, providing high-quality, customized solutions for various fields.

Classification of Foam Casting Molds

Classification by Material

Metal molds: Metal molds are usually made of cast iron, steel and other materials.

They are characterized by high strength, high hardness, good processability, low cost and long service life.

In mass casting production, metal molds are the first choice, especially for scenes with high requirements for mold strength and precision.

For example, in the casting of automobile engine parts, metal molds can withstand high temperature and high pressure casting environments to ensure the dimensional accuracy and surface quality of castings.

Plastic molds: The application of plastic molds is on the rise, especially after machinable plastics are introduced to the market and the life of plastic molds is improved, their application is becoming more and more extensive.

Plastic molds have the characteristics of light weight, relatively low cost and short production cycle.

Suitable for small batch production or cost-sensitive projects.

For example, for the casting of the shell of some electronic products, plastic molds can quickly produce samples for testing and improvement.

Ceramic molds: For iron casting, ceramic materials with high thermal tolerance and stability are usually used as foam mold casting materials.

Ceramic molds can withstand high temperatures, have good chemical stability, and are suitable for high temperature casting processes.

For example, in brass casting, ceramic molds can effectively avoid chemical reactions between mold materials and brass, ensuring the quality of castings.

Classification by function

Single-station mold: Single-station molds have a simple structure and are easy to operate.

They are suitable for the production of small batches and single products. Its advantages are low cost and simple maintenance.

For example, for the casting of some small handicrafts, single-station molds can meet production needs.

Multi-station mold: Multi-station molds can perform multiple processes at the same time to improve production efficiency.

Suitable for medium-volume production and can reduce production cycles.

For example, in the casting of some automotive parts, multi-station molds can complete the casting of multiple parts at the same time, improving production efficiency.

Compound mold: Compound molds can complete multiple processes in one stamping process, such as punching, blanking, bending, etc.

It has the characteristics of high production efficiency and high precision. It is suitable for casting parts with complex shapes.

For example, for the casting of the shells of some precision electronic products, compound molds can ensure the dimensional accuracy and surface quality of parts.

Fully automated molds: Fully automated molds use automated control systems, which can realize unmanned production, greatly improving production efficiency and product quality stability.

Suitable for mass production. In the fields of automobile manufacturing, electronic product manufacturing, etc., fully automated molds are widely used.

Hot runner mold: Hot runner molds keep the plastic in a molten state by heating the runner system, reducing plastic waste and molding cycle.

It is suitable for plastic foam casting, especially in the production of large plastic products.

For example, in the shell casting of some large household appliances, hot runner molds can improve production efficiency and product quality.

Steps for making foam casting molds

Prototyping

Prototyping is the first and most important step in making foam casting molds.

Computer-aided design (CAD) software is usually used for design, and then the prototype is made by 3D printing or hand-made.

The precision and accuracy of the prototype directly affect the quality of the subsequent mold.

For example, in the manufacture of some high-precision medical devices, the dimensional error of the prototype must be controlled within a very small range to ensure the quality of the final product.

Mold making

After the prototype is made, the mold is made next. Mold making can be done in a variety of ways, such as machining, EDM, etc.

For molds with complex shapes, CNC machining technology can also be used to improve machining accuracy and efficiency.

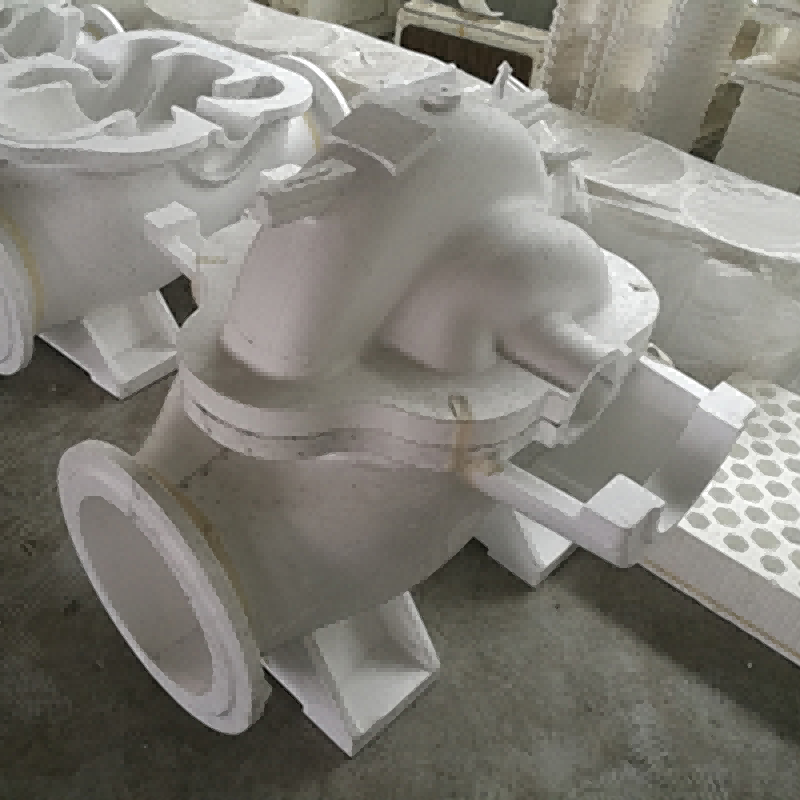

In foam casting, EPS foam molds are commonly used. EPS foam molds have the advantages of light weight, low cost, and short production cycle.

At the same time, EPS foam molds can also be customized as needed to meet the needs of different products.

EPS foam molds

EPS foam molds play a key role in foam casting.

EPS foam has good thermal insulation and cushioning properties, which can effectively protect castings from damage during the casting process.

In addition, EPS foam molds can also realize the manufacture of castings with complex shapes through mold design and processing.

For example, in the casting of automotive interior parts, EPS foam molds can produce parts with complex curves and surfaces, improving the aesthetics and comfort of the product.

Mortar coating

After the mold is made, mortar coating is carried out.

Mortar coating is to increase the strength and durability of the mold. Mortar coating can be carried out by manual coating or mechanical spraying.

During the coating process, it is necessary to ensure that the mortar is evenly covered on the mold surface to improve the strength and durability of the mold.

According to statistics, the strength of the mold coated with mortar can be increased by more than 30%, and the durability can be increased by more than 2 times.

This step is crucial to improving the quality and service life of the mold.

Advantages of different types of foam casting molds

Metal molds

Metal molds have the characteristics of high strength and hardness, which enables them to withstand greater pressure and impact during the casting process, thereby ensuring the dimensional accuracy and surface quality of the casting.

For example, in the casting of automobile engine cylinders, metal molds can ensure that the wall thickness of the casting is uniform, the surface is smooth, and the dimensional error is controlled within a very small range.

In addition, metal molds have good processability, and molds with complex shapes can be manufactured through various processing methods to meet the needs of different products.

Moreover, metal molds are low in cost and have a long service life, which has obvious economic advantages in mass casting production.

Plastic molds

Plastic molds are light in weight, easy to carry and operate, and reduce the labor intensity in the production process.

At the same time, plastic molds have a short production cycle and can respond quickly to market demand, especially suitable for small-batch production or projects with rapid product updates.

For example, in the casting of the shells of some electronic products, plastic molds can produce samples in a short time for testing and improvement, thereby speeding up product research and development.

In addition, the cost of plastic molds is relatively low, which is a good choice for cost-sensitive projects.

Ceramic molds

Ceramic molds have high thermal tolerance and stability, can withstand high-temperature casting processes, and are suitable for casting processes with high temperature requirements.

For example, in brass casting, ceramic molds can effectively avoid chemical reactions between mold materials and brass, ensuring the quality of castings.

At the same time, ceramic molds have good chemical stability and are not easily corroded by casting materials, which extends the service life of the mold.

Single-station molds

Single-station molds have simple structures and are easy to operate.

For the production of small batches and single products, they have the advantages of low cost and simple maintenance.

For example, for the casting of some small handicrafts, single-station molds can meet production needs, and do not require complex equipment and technical support, reducing production costs.

Multi-station molds

Multi-station molds can perform multiple processes at the same time, greatly improving production efficiency.

In medium-batch production, it can reduce production cycles and increase production capacity.

For example, in the casting of some automotive parts, multi-station molds can complete the casting of multiple parts at the same time, reducing the process conversion time in the production process and improving production efficiency.

Compound molds

Compound molds can complete multiple processes in one stamping process, such as punching, blanking, bending, etc., and have the characteristics of high production efficiency and high precision.

For the casting of parts with complex shapes, compound molds can ensure the dimensional accuracy and surface quality of parts.

For example, in the casting of the shells of some precision electronic products, compound molds can complete multiple processes at one time, reducing processing errors and improving product quality.

Fully automated molds

Fully automated molds use automated control systems to achieve unmanned production, greatly improving production efficiency and product quality stability.

In mass production, fully automated molds can reduce errors caused by manual operation, improve production efficiency and product quality.

For example, in the fields of automobile manufacturing and electronic product manufacturing, fully automated molds have been widely used, reducing production costs for enterprises and improving market competitiveness.

Hot runner molds

Hot runner molds keep the plastic in a molten state by heating the runner system, reducing plastic waste and molding cycle.

In plastic foam casting, hot runner molds are particularly suitable for the production of large plastic products, with the advantages of improving production efficiency and product quality.

For example, in the shell casting of some large household appliances, hot runner molds can ensure the fluidity of plastic in the runner, reduce product defects and improve product quality.

Material requirements for foam casting molds

Adhesive materials

Shengzhuo white mold cold glue: used for white mold bonding of foundry manufacturers, with high strength, low gas production, light weight, low glue consumption, strong and flexible glue layer, and easy cutting.

Mainly used for lost foam white mold bonding, no corrosion to the white mold, the joints will not separate, shift, or peel off after long-term drying in the drying room.

Cold glue for lost foam casting: It is in the form of emulsion, colorless and transparent, and can be directly applied to the EPS white mold model or the bonded surface of the foam board.

After a little airing, it can be aligned and pressed.

It is used in small amounts, has no residue, and has low gas production.

It is mainly used for large-scale bonding of white mold models, and is suitable for various processes such as lost foam casting of cast steel and cast iron.

Metal materials

Cast iron: In large-scale casting production, cast iron molds have the advantages of high strength, high hardness, good processability, low cost, and long service life.

Vermicular graphite cast iron with high heat fatigue resistance is also used as core box material.

More and more molds, mold bases, mold frames, etc. are made of ductile iron or low rare earth alloy gray cast iron with high strength and hardness.

Steel: With the improvement of mold processing technology and the increase in the requirements for dimensional stability of casting molds, mold steel and chromium-molybdenum alloy steel are also used to make casting molds.

In the past, they were mainly used for standard parts, inserts or liners on casting molds, and were rarely used to make casting mold bodies, because the service life of carbon steel is not higher than that of ductile iron or low alloy gray iron, and the price of alloy steel is expensive.

Casting materials

For iron casting, ceramic materials with high thermal tolerance and stability, such as alumina, are usually used as foam mold casting materials.

Aluminum casting usually uses foam mold materials, such as polystyrene foam or polystyrene foam coated silica sand (EPS/SLS) materials, because they can withstand lower casting temperatures.

Brass casting needs to consider the thermal conductivity of the mold material, and usually uses gypsum or other low thermal conductivity materials.

The material requirements for foam casting molds vary depending on different casting processes and product requirements.

When selecting materials, factors such as temperature tolerance, thermal conductivity, density and strength, chemical stability, cost and availability need to be considered to ensure a smooth casting process and obtain high-quality casting products.