Blow Molding Technology: The Key Technology to Shape Products

What is Blow Molding? Blow molding is a highly efficient manufacturing process used to produce hollow plastic parts. Think about the plastic bottles you drink

What is Blow Molding? Blow molding is a highly efficient manufacturing process used to produce hollow plastic parts. Think about the plastic bottles you drink

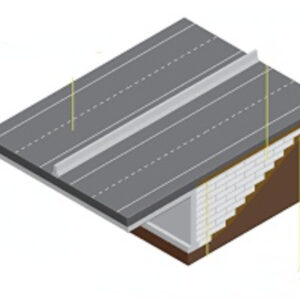

Geofoam is a lightweight engineered fill material made from expanded polystyrene (EPS) or extruded polystyrene (XPS) foam that has revolutionized civil engineering and construction projects

What Is Injection Molding Injection molding is a high-precision manufacturing process used to produce plastic parts in massive volumes with exceptional consistency and accuracy. This

Expandable Polypropylene (EPP) is a specialized foam plastic material that has revolutionized impact protection, thermal insulation, and lightweight design across multiple industries. Unlike conventional polypropylene,

Exterior foam trim molding has revolutionized modern construction by offering a lightweight, durable, and cost-effective alternative to traditional wood, PVC, or fiber cement trim. Whether

In today’s fast-moving industrial and consumer markets, packaging solutions need to be lightweight yet durable, cost-effective yet sustainable. Expanded Polypropylene (EPP) foam boxes have emerged as

In the evolving world of construction, the demand for energy-efficient, durable, and sustainable building materials is higher than ever. One innovation meeting these demands is

Ice boxes are portable containers used to refrigerate, preserve or freeze items, and are widely used in outdoor travel, medical transportation, food preservation, etc. As

As the holiday season approaches, craft enthusiasts and decorators alike search for innovative ways to create festive decorations. Styrofoam mini xmas tree molds have emerged

GEOFOAM is a lightweight, high-strength synthetic material with the following significant benefits in roadbed engineering: 1.Lightweight (significantly reduces load) Extremely low density: The density of

We adhere to the quality concept of “keep improving”, and strive to provide customers with the best products and services.

WhatsApp us

We will contact you soon,please pay attention to the email with the suffix”@epsole.com”.