EPS mold is a high-quality plastic mold with high strength, light weight, heat and sound insulation. Its name comes from the fact that it is made from Expandable Polystyrene (EPS) as a raw material through a process of heating, foaming and cooling. This kind of mold has excellent performance and a wide range of applications.

Features of EPS mold

- High strength and rigidity: EPS molds have high strength and rigidity and can withstand greater pressure and impact.

- Lightweight: Due to its lightweight characteristics, EPS molds are easy to transport and operate, which can reduce labor intensity.

- Thermal insulation: EPS molds have excellent thermal insulation properties, which can effectively reduce the temperature fluctuations of the molds.

- Good acoustic performance: EPS molds can absorb noise and provide a quiet working environment.

- Easy processing: EPS molds are easy to process, and can be easily produced in various shapes and sizes.

- Environmental protection: EPS molds can be recycled and reused, in line with environmental requirements.

Application of EPS molds

- Construction industry: EPS molds are widely used in the construction industry to make heat insulation materials, sound insulation materials.

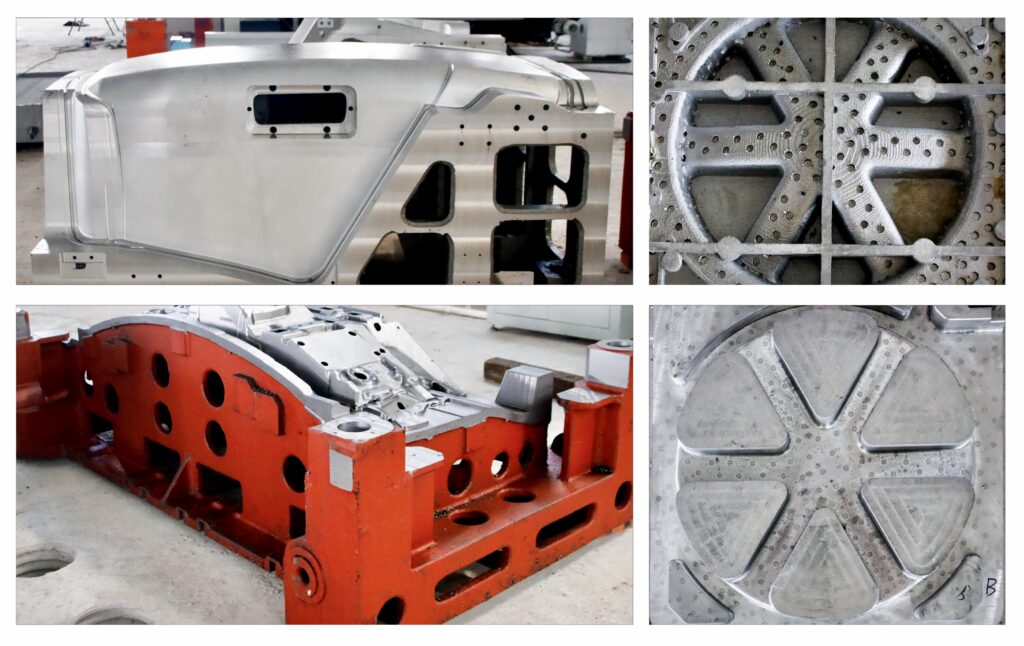

- Automotive industry: EPS molds can be used to make automotive parts, such as instrument panels, seats and so on.

- Other industries: EPS molds can also be used in packaging, logistics, agriculture and other fields.

Choose our EPS molds

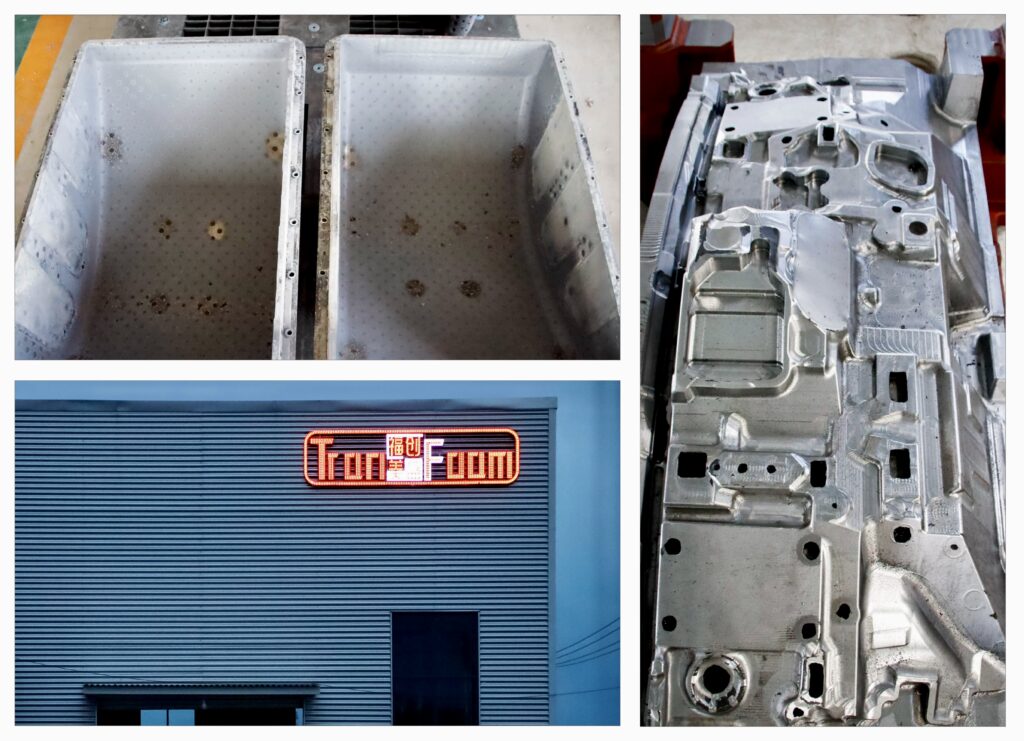

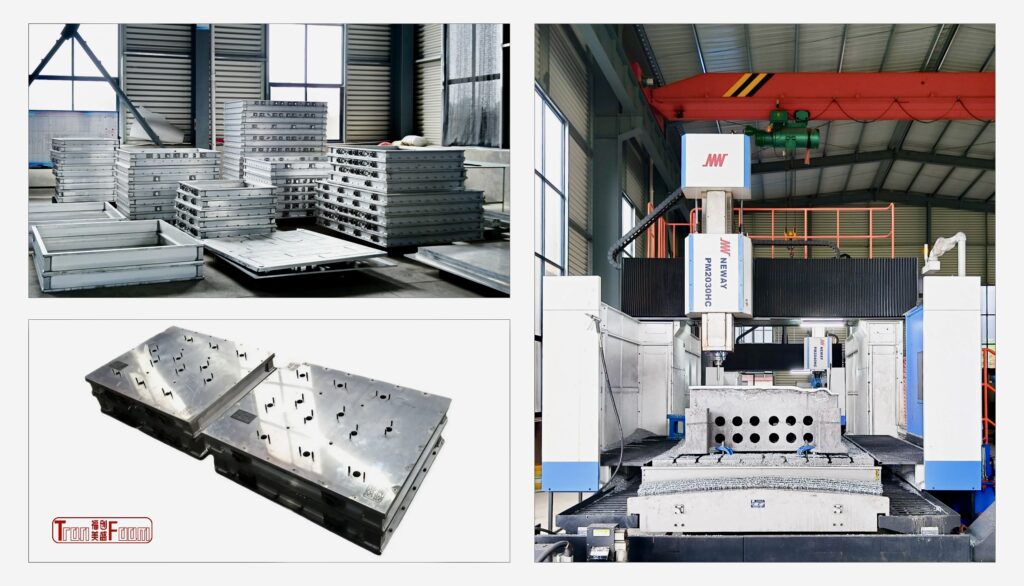

The EPS molds produced by our company adopt advanced production process and technology to ensure that the quality of our products reaches the highest standard. Our products have the following advantages:

Quality Assurance: We strictly control the raw material procurement, production process and quality testing to ensure that each product meets the national standards and customer requirements.