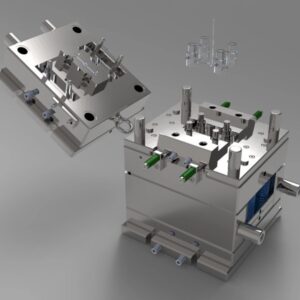

Injection Mold Design: Process, Principles, and Best Practices

Injection molding stands as one of the most versatile and widely used manufacturing processes globally, responsible for producing everything from microscopic medical components to massive